On this page

What is AS/RS racking:

AS/RS racking is storage engineered for automated cranes or shuttles. Uprights are the vertical columns that carry the load and keep the bays straight so robots can place and retrieve pallets reliably.

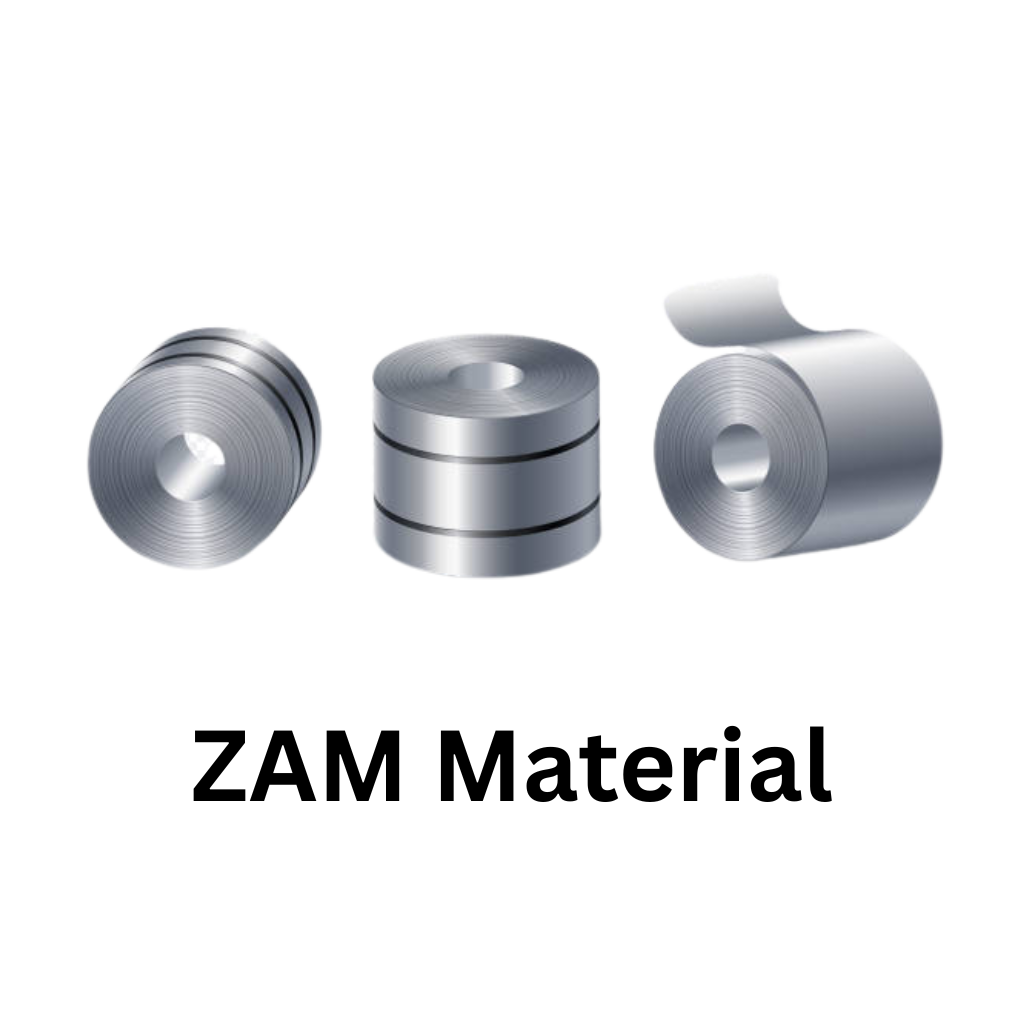

Two common upright constructions:

-

Roll-formed uprights: Coil steel formed on a roll-forming line, then punched. Light, highly repeatable, cost-efficient.

-

Structural/truss uprights: Thicker plate/sections welded into heavier columns or truss shapes. Very stiff and impact-tolerant.

Basics at a glance

-

Where roll-formed shines: Tight hole-pitch accuracy, fast throughput, consistent pallets, moderate seismic zones.

-

Where structural/truss shines: High-bay or deep-lane systems, frequent impacts, strict seismic/freezer specs, harsh environments.

-

Typical thickness (guide): Roll-formed ~1.6–3.0 mm; Structural/truss ~3.0–6.0+ mm.

-

Common hole pitch: 50 / 75 / 100 mm (follow your drawing).

-

Key limits: Beam deflection (e.g., L/200–L/250), upright plumb/straightness, and connector clearance windows.

-

Coatings: Powder coat for indoor; HDG galvanizing or duplex (HDG + powder) for corrosive, outdoor, or freezer sites.

People also ask (quick answers)

What is “unit-load” vs. “mini-load” vs. “shuttle”?

Unit-load = pallets via cranes; mini-load = totes/cartons; shuttle = carts running in lanes for multi-deep storage.

What is “storage depth”?

How many pallets deep per lane (single, double, multi-deep). More depth = more density but tighter stiffness/tolerance needs.

Static vs. dynamic load?

Static = in-position load. Dynamic = handling, impact, or seismic effects. Specs often call out both.

Why does hole-pitch accuracy matter?

Connectors and shuttle/crane interfaces reference those holes. If pitch drifts, you get install jams or rattles.

Which to pick?

| Factor | Roll-formed uprights | Structural / Truss uprights |

|---|---|---|

| Typical thickness (guide) | ~1.6–3.0 mm | ~3.0–6.0+ mm |

| Dimensional accuracy | Excellent pitch & cut-length via inline punching (CpK targets common) | Excellent stiffness; pitch depends on drilling/jigs |

| Impact resistance | Good with protectors; sensitive to repeated fork hits | Very high; better energy absorption |

| Seismic / high-bay | Moderate–high with proper bracing/anchors | High; preferred for strict seismic/high-bay |

| Deep-lane shuttle | Good for single/double-deep; multi-deep depends on deflection | Favored for multi-deep/high loads |

| Environment | Indoor/dry, powder coated | Harsh/outdoor/freezer; HDG or duplex |

| Cost & speed | Lower mass, fast line speeds, quick changeover | Heavier, more welding; slower, heavier duty |

| Best for | Standard unit-load, mini-load, many shuttle systems | Heavy unit-load, seismic, deep-lane, high-impact areas |

Quick chooser:

Pick roll-formed for accuracy and cost-speed when impacts are controlled.

Pick a structural/truss for stiffness and toughness when impacts, deep lanes, or seismic/freezer demands dominate.

Tolerances that keep robots happy

-

Hole pitch accuracy: target consistent pitch; maintain slot geometry for connector repeatability.

-

Upright plumb/straightness: stay within design limits to align pick faces and shuttle rails.

-

Connector clearance window: Too tight = install jams; too loose = rattle/re-torque.

-

Beam deflection: typically L/200–L/250 (as per design) to protect shuttle/crane alignment.

We can log dimensional checks (pitch, plumb, cut length) and provide summaries when requested in the RFQ.

Surface protection (what lasts)

-

Powder coat (indoor): 80–100 µm DFT typical; fast touch-up during install.

-

Hot-dip galvanizing (HDG): Superior corrosion resistance; mask contact areas needed for bolted/electrical interfaces.

-

Duplex (HDG + powder): Best life in aggressive or outdoor sites.

Manufacturing notes (so your drawings build cleanly)

Roll-formed lines

-

Inline punching supports consistent hole pitch & cut length at speed.

-

Cassette tooling enables fast changeovers across profiles.

-

Ideal when connector geometry repeatability and throughput are priorities.

Structural/truss fabrication

-

Laser/plasma cutting + drilling + fixture-controlled welding for heavy sections.

-

Suits complex nodes, thick footplates, seismic gussets, and impact zones.

-

Dimensional control via weld jigs and verified datums.

Example scenarios

-

Unit-load crane AS/RS, 2-deep, moderate seismic, controlled MHE: Roll-formed uprights, inline-punched pitch, powder coat; add guards.

-

Shuttle AS/RS, 4-deep, high bay, frequent touches: Structural/truss uprights with heavier footplates and HDG/duplex finish.

-

Freezer AS/RS with strict anchors and condensation risk: Structural uprights, HDG, sealed hardware packs, low-temp gaskets.

RFQ checklist (build-to-spec)

Include with your drawings/specs:

-

Models & 2D drawings for uprights, beams, bracing, footplates (tolerances + datums).

-

Hole pitch standard (50/75/100 mm) and connector geometry with allowable clearance.

-

Load cases: static, dynamic, seismic inputs; deflection targets (e.g., L/x).

-

Environment & coating: powder/HDG/duplex; DFT or zinc mass requirements.

-

Anchoring: baseplate thickness, hole pattern, anchor spec.

-

QC deliverables: dimensional check sheets, coating DFT logs, weld PQR/WPS, material certs.

-

Kitting/packaging: bay-level kits, sequence labels, QR linking drawings for fast aisle builds.

-

Site constraints: install sequence, lift/door clearances, staging limits.

FAQs

Is roll-formed always cheaper?

Often on unit cost and cycle time, yes. But if damage risk or seismic demands are high, structural can be cheaper over the full life.

Can we mix types?

Yes. Many projects use roll-formed in standard bays and structural at cross-aisles, tunnel ends, or mezzanine interfaces.

What helps most during install?

Accurate hole pitch, clear kitting/labels, masked contact areas, and a coating repair kit for touch-ups.

Next step

Upload your AS/RS rack drawings, load cases, environment, and delivery window. We’ll return a firm lead time, QC pack scope, and quote aligned to your rollout plan.