On this page

Local Saudi manufacturing helps data centers hit IKTVA targets, lock delivery windows, and lower total cost of ownership—without compromising spec or quality.

Why local cabinets reduce TCO

-

Lead times in weeks, not months. Regional fabrication and finishing reduce idle-site costs and LD exposure.

-

Lower logistics cost and damage. No ocean freight, diversions, or re-crating rework.

-

Faster change control. Late-stage tweaks (cutouts, baffles, anchoring) are turned around quickly.

-

Serviceable spares on shelf. Doors, side panels, rails, locks, and seals available locally.

-

Compliance packaged. Load/bonding test reports, coating certs, serialised QC—ready for operator checks.

Illustrative example:

Imported landed unit: $1,950 vs. local unit: $1,800.

Avoiding a 7-day delay across a 20-rack row at $1,200/day = $24,000 schedule risk avoided.

Net: the schedule win outweighs small unit deltas.

How local cabinets lower project risk

-

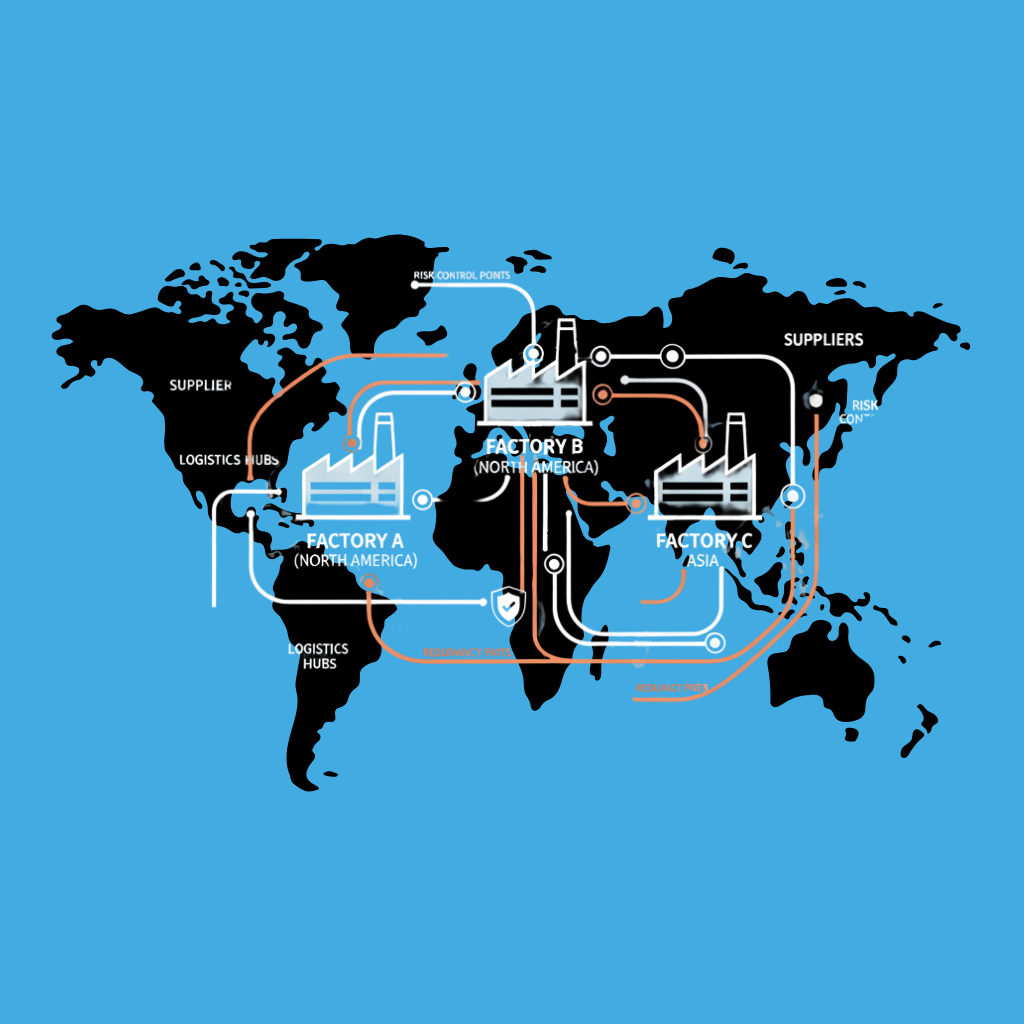

Schedule certainty. No vessel rollovers or port congestion; predictable FAT and delivery slots.

-

Spec fidelity. Built to your drawings; witnessed load tests and continuity logs on request.

-

Accountability in-country. One team for fabrication, coating, assembly, and fitment support.

-

Regulatory alignment. Documentation aligned to Saudi operator standards and site acceptance.

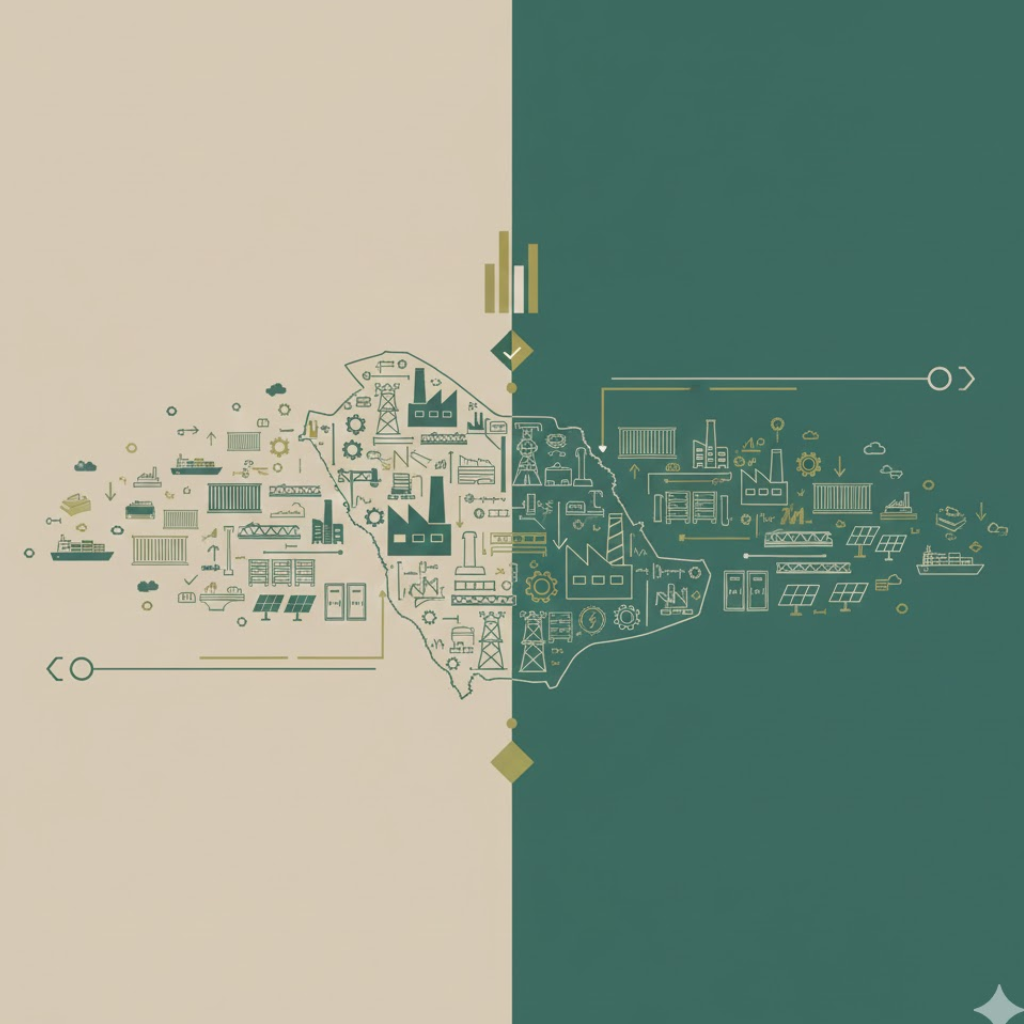

IKTVA advantages for buyers

-

Score contribution. Local value add across fabrication, coating, assembly, and testing supports your IKTVA objectives.

-

Ecosystem uplift. Path to localize accessories (PDUs, cable managers, glass, locks) for additional IKTVA credit.

-

Audit-ready trail. Traceable materials, process logs, payroll/CapEx evidence for verification.

Technical essentials we support

-

Form factors: 19″ EIA-310 (common), 21″ OCP, 23″ telecom (as per your drawings).

-

Sizes: 800 W × 1100/1200 D; 42U–52U heights; adjustable rails with clear U-marking.

-

Load ratings: ≥1200 kg static, ≥800 kg dynamic (caster tests), seismic/anchor options on request.

-

Earthing & bonding: M8/M10 earth stud, masked landings, braided door/panel straps, continuity targets ≤0.1 Ω logged per serial.

-

Airflow: ≥70% perforated doors, blanking panels, side air-seals, brush grommets; containment-ready roof/door interfaces.

-

Finishing: Powder coat 80–100 µm, salt-spray hours per environment; coating certificates included.

-

QC pack: Load/bonding readings, coating certs, assembly drawings, spare parts list.

RFQ: files and details to include

-

Models & drawings: STEP (.stp/.step) and 2D DXF/DWG/PDF with tolerances, hole patterns, U-marking.

-

BOM: Materials/gauges, hardware (hinges, locks, gaskets), glass, filters.

-

Performance targets: Static/dynamic load, deflection limits, seismic/anchoring requirements.

-

Electrical: Earthing stud spec (M8/M10), continuity target (e.g., ≤0.1 Ω).

-

Thermal/airflow: Door open-area %, blanking plan, side baffles, containment interface.

-

PDU & cable layout: 0U PDU brackets, vertical managers, rear finger ducts.

-

Finish: RAL/PANTONE, film build (µm), corrosion hours.

-

Documentation: Required test reports (load, bonding) and certificates.

-

Logistics: Required-by date, delivery sequencing, crate/lift constraints, site access.

Buyer checklist

-

Delivery window aligned to white-space schedule (FAT → ship → install).

-

Serialised QC pack per cabinet (bonding readings, load test reference).

-

Local spares commitment (doors, panels, rails, locks).

-

Containment/PDU interfaces confirmed before FAT.

-

Pilot row install to validate fit, earthing, and airflow.

FAQs

Will local always be cheapest per unit?

Not always. But when you include schedule certainty, avoided rework, and local service, total installed cost usually drops.

Are global OEM servers compatible?

Yes. We build to your drawings and EIA-310; rails, U-labels, and PDUs follow standard OEM conventions.

Can you support seismic requirements?

Yes—reinforced bases, anchor kits, and GR-63-style testing are available on request.

Next step

Upload your drawings and specifications with target loads and delivery window. You’ll receive a firm lead time, DFM notes for your approval, and a detailed quote—so you can lock TCO and IKTVA outcomes.