On this page

If you want to improve local content fast, don’t start with “strategy.” Start with what moves the score and what buyers can verify.

Most local content frameworks in KSA are built around spend that happens in Saudi across goods & services, employee compensation, asset depreciation, and capacity building.

Below is a fast, realistic way to lift your local content in 30–90 days without turning your business upside down.

Step 1: Know what you’re trying to improve (the “score levers”)

A clean way to think about it is:

-

Goods & Services spent in Saudi

-

Employee compensation in Saudi

-

Asset depreciation in Saudi (equipment, facilities)

-

Capacity building (training, R&D, supplier development)

And in tenders, you’ll often see mechanisms like Mandatory List, SME preference, and local content weight in financial evaluation (especially with state-owned entities).

The fastest wins (what usually moves the needle first)

1) Flip procurement spend to Saudi, fast

This is usually the quickest lever because it doesn’t require new machines.

Do this in 2–4 weeks:

-

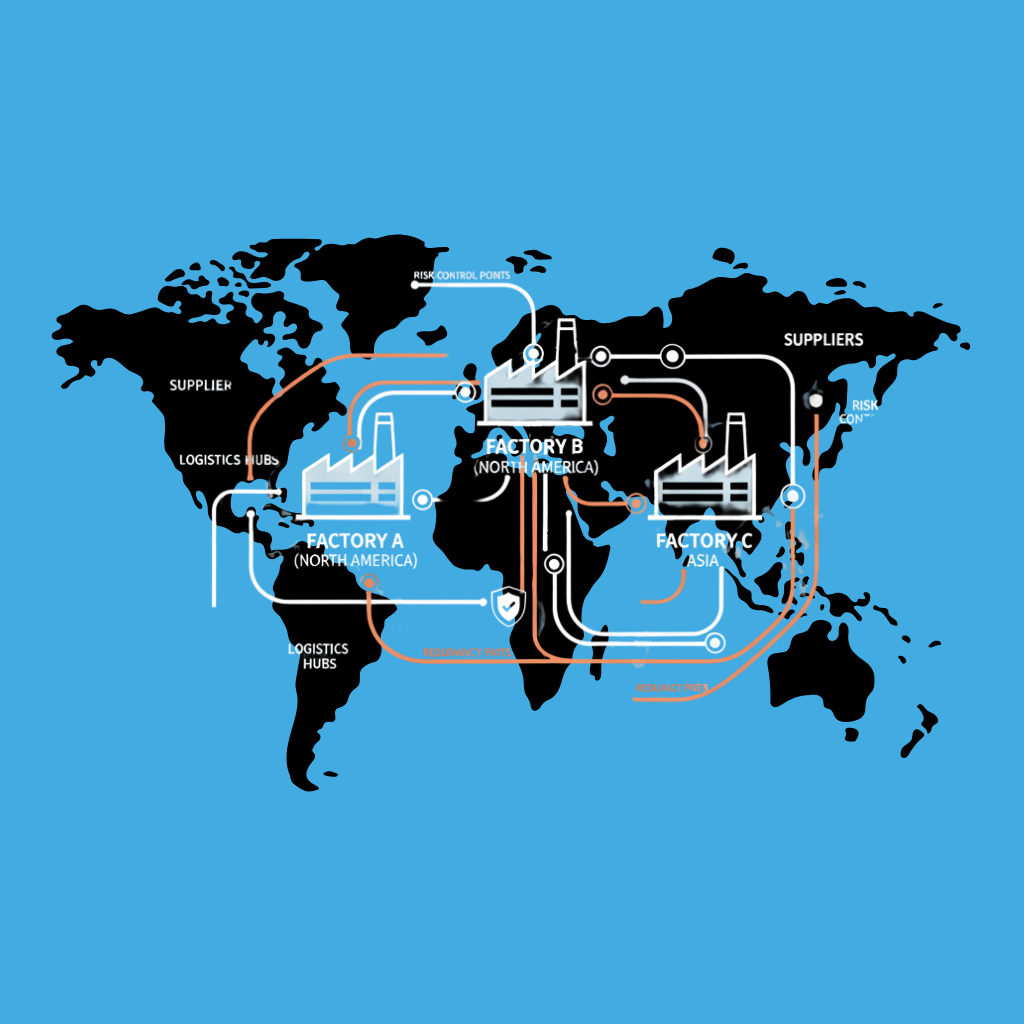

Identify your top 20 spend categories (raw material, coating, packaging, logistics, tooling, consumables, subcontracting).

-

For each category, create a “Saudi alternative” shortlist and start dual-sourcing.

-

Convert imported service lines into Saudi-based vendors where possible: logistics, warehousing, packaging, local machining, coating, NDT, testing.

What to document (buyers love this):

-

Saudi vendor invoices + contracts + delivery records

-

Local supplier qualification checklist

-

“Local content evidence pack” (more on this below)

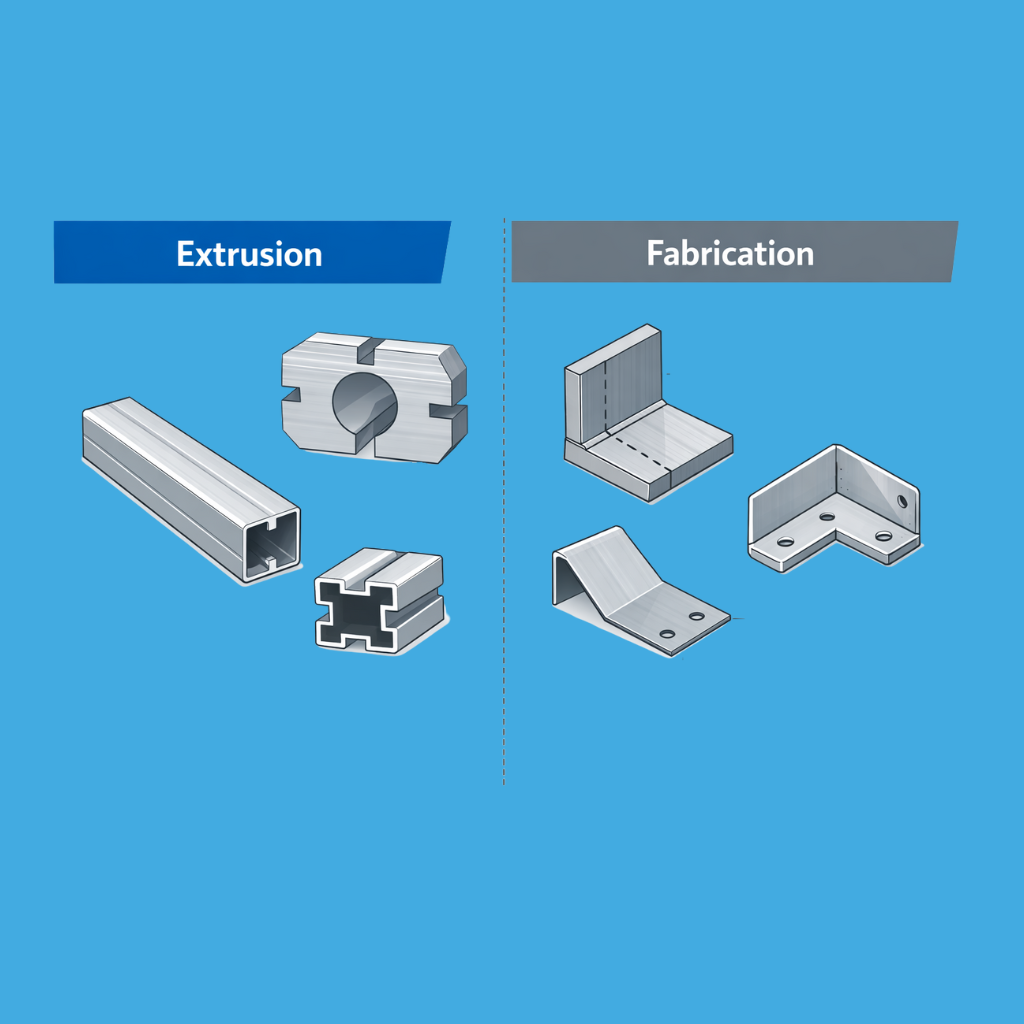

2) Move one or two value-add steps into KSA (even if you keep some imports)

Buyers don’t just care that you have an office in KSA. They care where value-add happens.

Fast localization options (30–60 days):

-

Local final assembly + QC in Saudi

-

Local powder coating / galvanizing / finishing

-

Local kitting + packaging + labeling

-

Local sub-assembly (brackets, frames, panels, hardware kits)

Even if raw material is still imported, shifting value-add steps locally can materially improve your “Saudi spend” footprint and tender confidence.

3) Fix payroll and org structure so Saudi spend is real

Local content models include employee compensation in Saudi as a component.

Quick moves:

-

Hire Saudis into roles that matter for delivery: QA, production supervision, supply chain, project coordination.

-

Ensure salaries are paid through Saudi payroll and appear cleanly in your Saudi financials.

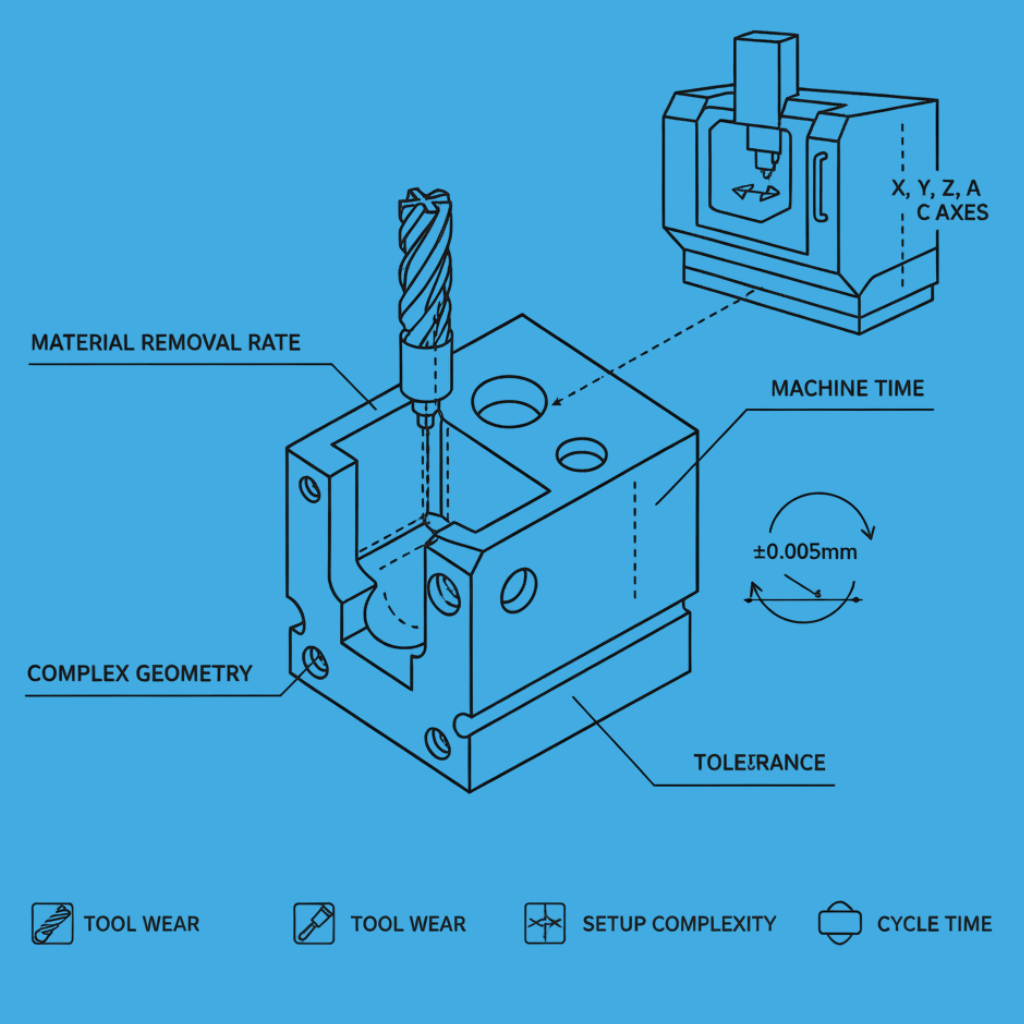

4) Make one “capex move” that’s small but defensible

You don’t need a huge factory expansion to show progress. One smart capex action can unlock credibility.

Examples:

-

One machine that directly supports your deliverables (press brake, welding set-up, basic machining, inspection equipment)

-

Tooling/fixtures that permanently stay in KSA

-

A dedicated QC lab corner (calibration, gauges, documentation discipline)

Asset depreciation in KSA is explicitly part of the local content calculation approach.

5) Put “capacity building” on paper and make it real

Capacity building is often underused because suppliers don’t track it properly, even when they do it.

Fast wins:

-

Training calendar for Saudi team (safety, quality, process, inspection)

-

Supplier development: onboarding 2–3 local subcontractors and training them to your standards

-

Simple R&D / process improvement log (even small improvements count if tracked properly)

Capacity building is a named element in local content components.

A simple 30–90 day execution plan

First 10 days: baseline + proof

-

Build a “local content tracker” from your financials (what spend is actually in KSA).

-

Create an evidence folder structure (invoices, payroll, vendor CRs, contracts, delivery notes).

Tip: Saudi tender ecosystems also provide templates and local content documents by project cost via Etimad’s template section.

Day 10–30: quick spend switch

-

Shift 10–20% of key vendor spend to Saudi vendors.

-

Lock 2–3 Saudi subcontractors for finishing / assembly / packaging.

Day 30–90: operational localization

-

Bring at least one permanent value-add step into KSA.

-

Add one capex item that supports that step.

-

Formalize Saudi payroll and training cadence.

The “Local Content Evidence Pack” (what to hand a buyer in one PDF)

Include:

-

Facility address + photos + process list (what steps happen in KSA)

-

List of Saudi suppliers + scope + monthly spend

-

Sample invoices (redacted) proving Saudi procurement

-

Saudi payroll proof (headcount + functions)

-

QA documents: ITP, inspection reports, calibration logs

-

Local content certificate (if applicable)

Local content certification is widely treated as a structured verification of contribution based on standardized criteria (local sourcing, Saudi employment, local investment).

Common mistakes that slow suppliers down

-

Your KSA entity exists, but invoices are issued from outside KSA. Buyers will treat it as non-local spend.

-

You “assemble” in KSA but can’t show repeatable QA + traceability.

-

Your product specs accidentally exclude national products (this is explicitly flagged as something entities should avoid in tendering).

-

You don’t track data in the format tenders ask for (so you scramble at submission time).

Why acting now matters (2026 pressure)

Public reporting indicates the mandatory national products list is expected to expand toward 2,000 items in 2026, which will increase “local-first” sourcing pressure across more categories.