On this page

ZAM (Zn-Al-Mg) coated steel: the buyer’s & manufacturer’s guide

We build to your drawings/specs. If you’re considering ZAM (Zn-Al-Mg) for stamped, bent, or welded parts, share your model + 2D and coating weight (e.g., ZM120/ZM275); we’ll quote to spec.

What is “ZAM” material? (quick answer)

“ZAM” is shorthand for zinc-aluminum-magnesium hot-dip coated steel. The coating chemistry (small % of Al and Mg in a Zn bath) gives much better corrosion resistance and cut-edge protection than standard galvanizing. Typical branded products include ZAM® (Nippon Steel), Magnelis® (ArcelorMittal), PosMAC® (POSCO), and SuperDyma® (JFE).

What is ZAM material used for in manufacturing?

Common applications: outdoor cabinets/enclosures, solar/racking, HVAC housings and panels, cable trays, guardrails, automotive brackets and underbody parts, and any sheet-based component where painted GI struggles at edges, laps, and scratches. These brands publish outdoor/cut-edge performance data showing strong gains vs. GI.

Who offers ZAM-type products suitable for automotive parts?

-

Nippon Steel – ZAM® (Zn-6%Al-3%Mg) with published coating density and datasheet. Automotive applications via Wheeling-Nippon in the US also reference ZAM. (Nippon Steel)

-

ArcelorMittal – Magnelis® (Zn-3.5%Al-3%Mg). Used in transport/automotive and structural parts; current technical books and spec tables available. (constructalia.arcelormittal.com)

-

POSCO – PosMAC® (e.g., Zn-3%Mg-2.5%Al family). POSCO documentation highlights automotive/chassis and BIW-adjacent uses. (Ecomedes Library)

-

JFE – SuperDyma® (Zn-Al-Mg-Si). Longstanding Zn-Al-Mg variant used in automotive and appliances. Nippon Steel

Tip for RFQs: Ask mills/service centers for EN 10346 “ZM” designations (e.g., ZM120/ZM275) with base steel grade (DX51D, S350GD, etc.).

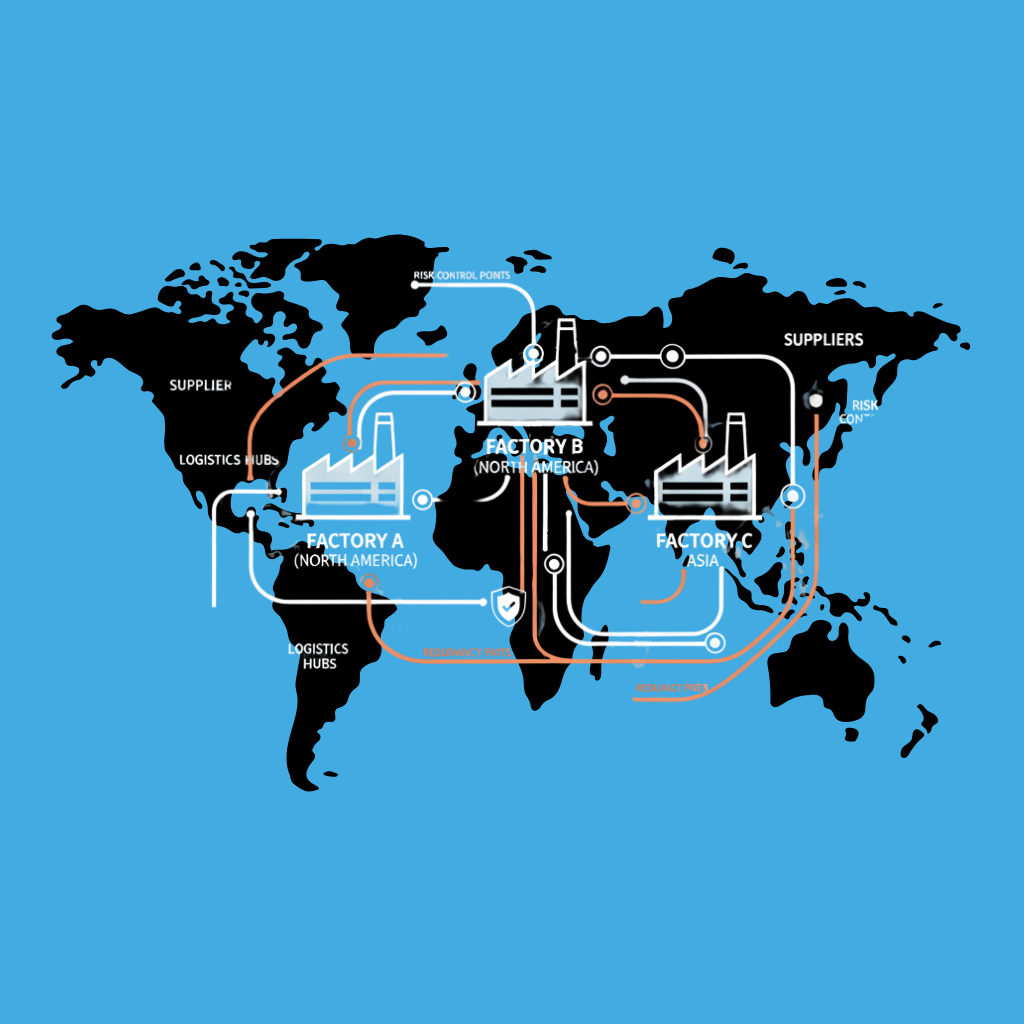

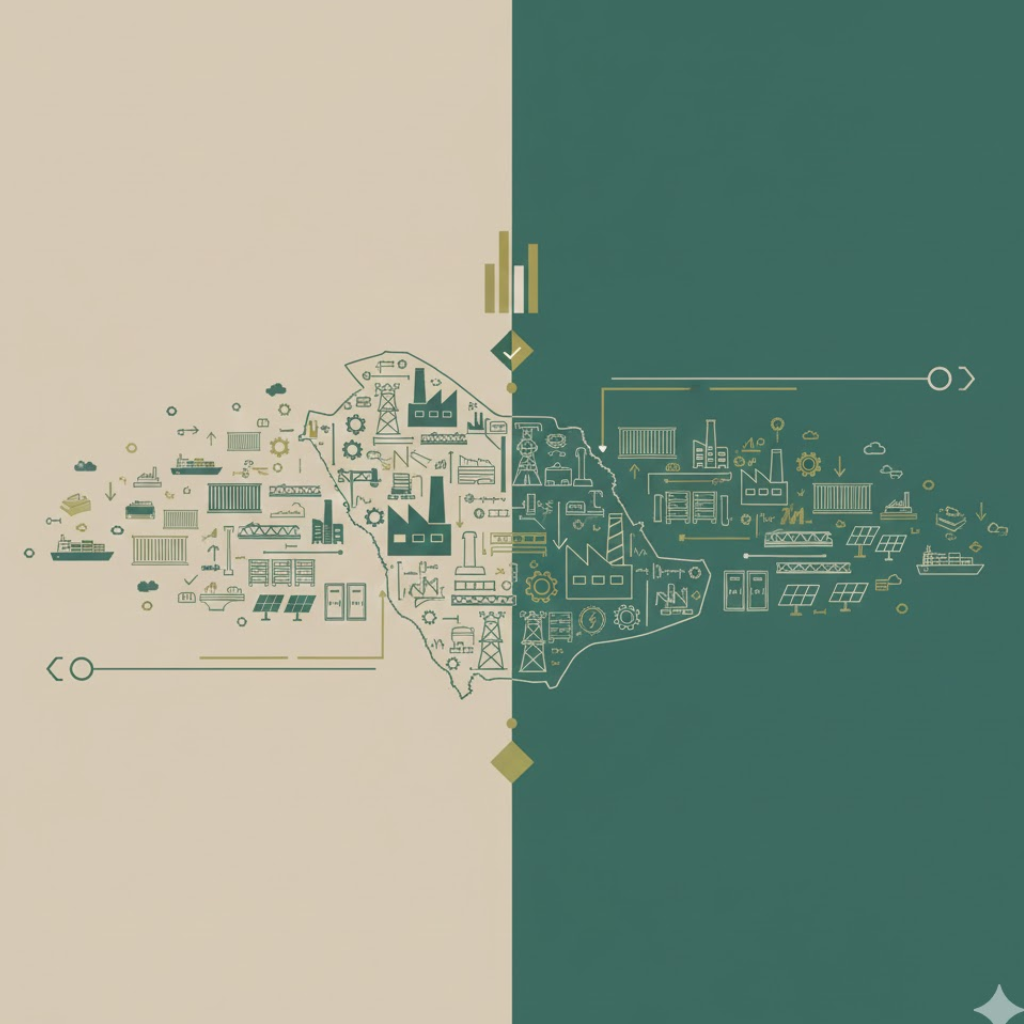

Where can I find suppliers of ZAM material in Saudi Arabia?

-

Regional distributors/importers that stock Magnelis/ZN-Al-Mg and serve KSA projects (solar, infrastructure). Example: Perfect Structure Solutions (KSA) markets Magnelis-coated solutions locally.

-

Mill/regional channels: contact ArcelorMittal (Constructalia/Downstream Solutions) for Magnelis supply into GCC; POSCO International Middle East and trading listings show presence in Dammam/GCC. Many shipments route via UAE service centers into KSA.

Reality check: Local coil production of Zn-Al-Mg in KSA is limited; most buyers import coils/sheets from EU/Asia via regional processors. Ask for mill test certificates (MTCs) and EN 10346 ZM labels with each batch.

How to identify genuine ZAM products (quick checklist)

-

Datasheet + brand on the quote/COC: ZAM®/Magnelis®/PosMAC®/SuperDyma® (or equivalent Zn-Al-Mg).

-

EN 10346 ZM designation printed on tags (e.g., ZM120, ZM275) + base grade (DX51D, S350GD).

-

Coating weight & density listed on certs (e.g., Magnelis density ~6.2 g/cm³, ZAM ~6.0 g/cm³ for coating thickness calcs).

-

Mill certs (MTCs) showing chemistry, coating mass (g/m² both sides), mechanicals.

-

Independent lab tests (if needed): coating mass, adhesion, salt-spray to verify claims.

Compare properties: ZAM vs. other zinc coatings (at a glance)

| Property | ZAM-type (Zn-Al-Mg) | GI (pure Zn) | GA (galvannealed) | Al-Zn (e.g., Galvalume) |

|---|---|---|---|---|

| Cut-edge protection | Best in group (self-healing corrosion products) | Fair | Fair–Good | Good |

| General corrosion | High at a given g/m² | Moderate | Moderate–High | High |

| Formability | Good; watch tool wear | Good | Good paint base | Good (watch tight-bend micro-cracks) |

| Typical composition | Zn with ~3–6% Al and ~1–3% Mg (brand-specific) | ~100% Zn | Zn-Fe alloy layer | ~55% Al, balance Zn (varies) |

| Coating density (coating layer) | ≈6.0–6.2 g/cm³ (brand-specific) | ~7.1 g/cm³ | ~7.1 g/cm³ | ~3.7 g/cm³ (varies) |

Sources & examples: Magnelis (Zn-3.5%Al-3%Mg; density 6.2 g/cm³), ZAM® (Zn-6%Al-3%Mg; coating density 6.0 g/cm³).

ZAM material composition (by brand examples)

-

Nippon Steel ZAM®: Zn-6%Al-3%Mg (coating).

-

ArcelorMittal Magnelis®: Zn-3.5%Al-3%Mg (coating).

-

POSCO PosMAC®: family around Zn-~3%Mg-~2.5%Al; multiple variants (1.5/3.0).

-

JFE SuperDyma®: Zn-Al-Mg-Si alloyed coating; automotive usage documented.

Density note: These densities refer to the coating, not the steel substrate. Base low-carbon steel density remains ~7.85 g/cm³; coating density is used when converting g/m² to µm. Magnelis tables explicitly list 6.2 g/cm³; ZAM tables use ~6.0 g/cm³ for thickness calculations.

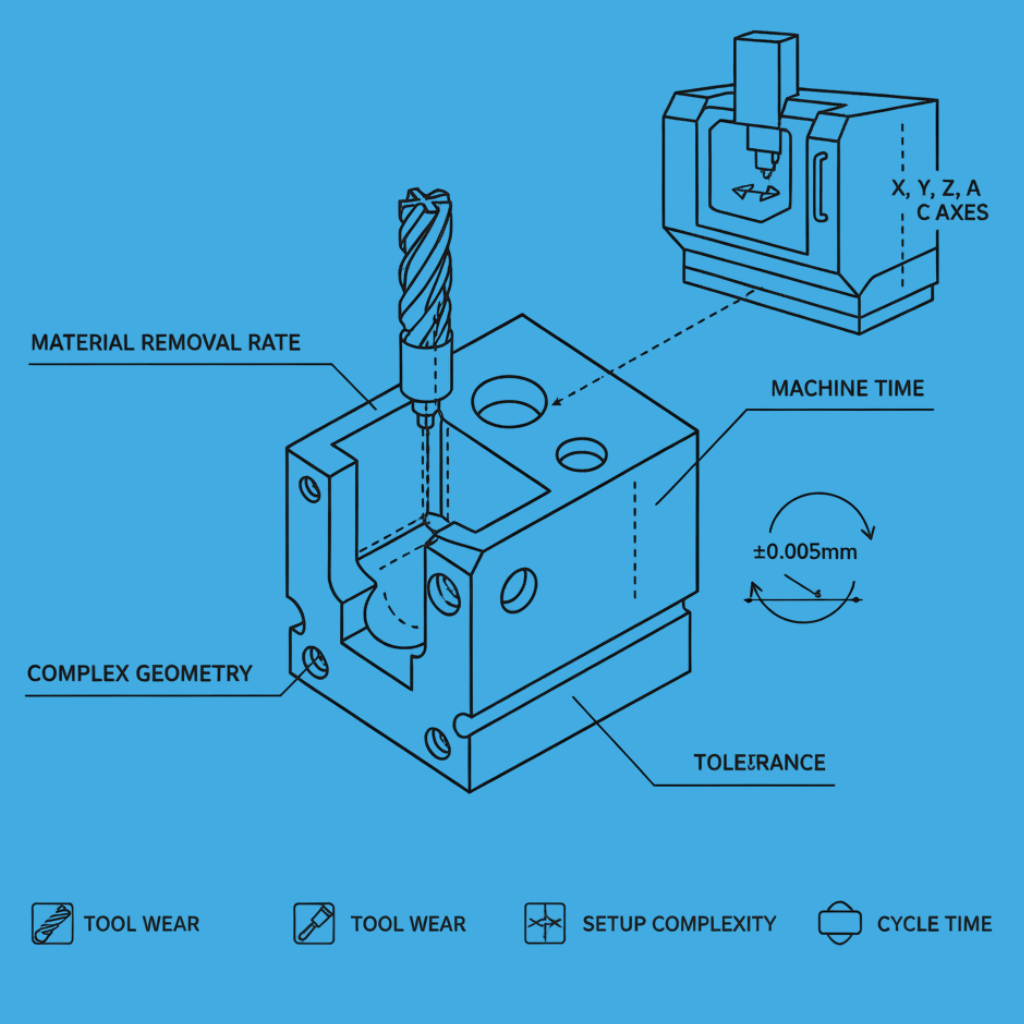

ZAM material properties that matter on the shop floor

-

Corrosion resistance: significantly higher than GI at the same coating weight; especially strong at cut edges/laps. Independent and mill studies support this.

-

Forming & stamping: good; plan proper lubrication and monitor tool wear vs. GI.

-

Welding: spot/MIG weldable with parameter tweaks; manage zinc fumes with extraction. (See brand welding notes in datasheets.)

-

Powder-coat/paint: works well with correct pretreatment; edge prep still matters.

ZAM material specification + PDFs (starter pack)

-

Nippon Steel ZAM® product catalog (composition, density, thickness calc). (Nippon Steel)

-

ArcelorMittal Magnelis® technical book/spec (EN 10346 “ZM”) with coating weight ↔ thickness tables and properties. (ArcelorMittal Industry)

-

POSCO PosMAC® datasheet/tech brief (1.5/3.0 variants, applications including automotive). (steel-n.com)

-

JFE SuperDyma® tech paper (Zn-Al-Mg-Si) for background and automotive context. (Nippon Steel)

Save these to your internal library and reference the ZM coating code in your RFQs.

Sourcing in Saudi Arabia: how to proceed

-

Ask for EN 10346 ZM on the quote (e.g., ZM120/ZM175/ZM275) + base steel grade (DX51D, S350GD…).

-

Ping regional channels:

-

ArcelorMittal (Magnelis) via Constructalia/Downstream Solutions (GCC supply).

-

POSCO International reps covering KSA/GCC (Dammam listing).

-

Local integrators using Magnelis (e.g., PSS KSA for solar structures) can resell/advise.

-

-

Verify authenticity with MTCs, ZM code on coil tags, and coating density used in thickness calcs.

RFQ checklist (copy/paste)

-

Base grade + thickness: e.g., DX52D / S350GD, t = 1.2 mm

-

Coating: ZM with weight (e.g., ZM175), brand acceptable (ZAM/Magnelis/PosMAC/SuperDyma)

-

Finish plan: bare or powder-coated (color, DFT), adhesion tests if painted

-

Operations: stamping/bending/laser/weld; target burr/flatness

-

Environment & life: inland/coastal/industrial; any salt-spray requirement

-

Docs: MTC, coating mass cert, adhesion or corrosion reports if required

-

Packaging: VCI, separators, edge protection; labels/barcodes

-

Timeline: pilot qty, PPAP/FAI, SOP

Work with a team that already builds in ZAM (Zn-Al-Mg)

We’ve produced ZAM/Magnelis/PosMAC/SuperDyma parts across solar, data centers, aerospace (ground), HVAC, racking, and windows/doors. If you’re unsure which alloy, coating weight, or process route to choose, we’ll guide you.

What to send us (redacted is fine):

-

Drawing/photo + thickness

-

Target service life & environment (inland/coastal/industrial)

-

Expected volumes (pilot, monthly, annual)

What you’ll get back from us:

-

Material recommendation (ZAM / Magnelis / PosMAC / SuperDyma) and ZM coating weight (e.g., ZM150/ZM175/ZM275)

-

Manufacturing route suggestions (stamping vs. laser-bend, forming radii, weld notes, pretreatment/powder stack)

-

Lead-time signal based on regional availability and finishing

Next step:

Attach your file or Contact us —we’ll review and respond with a practical, build-ready recommendation and a quote path.

FAQs

1) How do ZAM coatings compare to standard GI on density and thickness calculations?

Magnelis uses ~6.2 g/cm³ and ZAM catalog uses ~6.0 g/cm³ for converting g/m² to µm; GI uses zinc’s ~7.1 g/cm³. That’s why ZM coatings can achieve similar or better protection at thinner thickness for the same mass.

2) Is ZAM truly better at the cut edge?

Yes. The Al/Mg additions form protective corrosion products that self-heal edges and scratches more effectively than pure zinc. Multiple studies and brand docs show this effect.

3) Do you design parts or build to spec?

We manufacture to your drawings and specifications (build-to-print). Send models + 2D, we produce and supply QC docs.

4) Can ZAM be stamped and bent?

Yes. It forms well. Use proper lubrication and plan reasonable inside radii (≈ material thickness as a safe start).

5) Is ZAM weldable?

Yes—spot and MIG are common. Expect slight parameter tweaks vs. GI and use fume extraction for zinc fumes.

6) Can I powder-coat ZAM?

Yes. Clean + pretreat (phosphate/zirconium per your system) for strong adhesion. Deburr sharp edges before coating.

7) What coating weights should I specify (EN 10346 “ZM”)?

-

Indoor/light outdoor: ZM120–ZM150

-

General outdoor: ZM150–ZM175

-

Coastal/harsh: ZM175–ZM275

Choose per environment and target lifetime.