On this page

In today's complex global economy, many procurement leaders feel like they're managing a roster of strangers rather than a team of partners. You issue purchase orders (POs), negotiate prices, and demand results, but the collaboration often stops there. This traditional, arm's-length approach to supplier management is no longer just inefficient—it's a significant business risk.

The companies that are winning in 2025 are not those with the largest list of vendors, but those with the deepest, most collaborative partnerships. They are moving beyond the transactional to embrace the Integrated Vendor Model (IVM), a new framework for creating powerful, resilient, and innovative supply chains.

The Problem with Traditional, Transactional Procurement

For decades, the procurement playbook was simple: negotiate hard, maintain distance, and focus relentlessly on cost reduction. This model worked in a more predictable world, but it is failing to meet the challenges of today.

Modern businesses are grappling with pressures the old model was never designed to handle:

-

Constant Supply Chain Disruptions: Geopolitical events, logistical bottlenecks, and climate events can cripple operations without warning.

-

Strict ESG & Compliance Demands: Stakeholders demand transparency and sustainability throughout the entire value chain, not just within your own four walls

-

The Need for Unprecedented Speed: Customers expect rapid innovation and customization, which requires deep collaboration with suppliers.

When you turn to a transactional supplier for help with these complex issues, you often find they are siloed and reactive—because the relationship was designed that way.

What is an Integrated Vendor Model (IVM)?

An Integrated Vendor Model (IVM) fundamentally flips the script on supplier relationships. It treats select suppliers not as external entities, but as strategic partners who are deeply embedded within your operational ecosystem.

Under an IVM, a supplier becomes an extension of your team. This model is characterized by:

-

Seamless Systems Integration: Your partner’s systems (like ERP and MES) communicate with yours in real-time, providing shared visibility into inventory, production, and forecasting.

-

Collaborative Goal Setting: Partners actively participate in your strategic processes, from product design and demand forecasting to achieving sustainability targets.

-

Shared KPIs and Performance Metrics: Success is measured by your key performance indicators (KPIs)—like on-time delivery to your end-customer or reduced product development cycles—not just the supplier's internal metrics.

-

Mutual Risk & Reward Sharing: The partnership is structured so that both parties have a vested interest in overcoming challenges and capitalizing on opportunities together.

In short, your vendors stop acting like strangers and start acting like valued teammates who are invested in your success.

The Key Drivers Behind the Shift to IVM in 2025

This is not just a theoretical concept; it's a strategic shift driven by powerful market forces:

-

Digital Transformation: Cloud-based platforms, IoT, and real-time analytics have made it technologically seamless to integrate a partner’s data and workflows directly into your own.

-

Resilience Over Cost: In a volatile world, the value of a reliable partner who can help you navigate a crisis far outweighs the minor savings from squeezing a transactional vendor on price.

-

ESG and Value Chain Transparency: Meeting ambitious sustainability and compliance goals is impossible without deep alignment and data sharing with your key suppliers.

How to Implement an Integrated Vendor Model: A 4-Step Framework

Transitioning to an IVM requires a deliberate, strategic approach.

-

Step 1: Segment and Audit Your Supplier Portfolio: Identify which suppliers have the capabilities, technology, and—most importantly—the mindset to become true partners. Not every vendor needs to be integrated.

-

Step 2: Invest in Collaborative Technology: Ensure your ERP, procurement software, and communication platforms are capable of supporting real-time data exchange and deep collaboration.

-

Step 3: Redefine Your Performance Metrics (KPIs): Move beyond cost and on-time-in-full (OTIF). Develop a balanced scorecard that measures innovation, responsiveness, sustainability contributions, and shared risk mitigation.

-

Step 4: Cultivate a Partnership-Oriented Culture: Train your procurement, engineering, and operations teams to view key suppliers as co-creators of value, not just line items on a budget.

Build Your Competitive Advantage with a True Integrated Partner

The future of procurement belongs to leaders who can build smarter, deeper, and more resilient supplier ecosystems. The first step is to find a partner who is built to operate as an extension of your team.

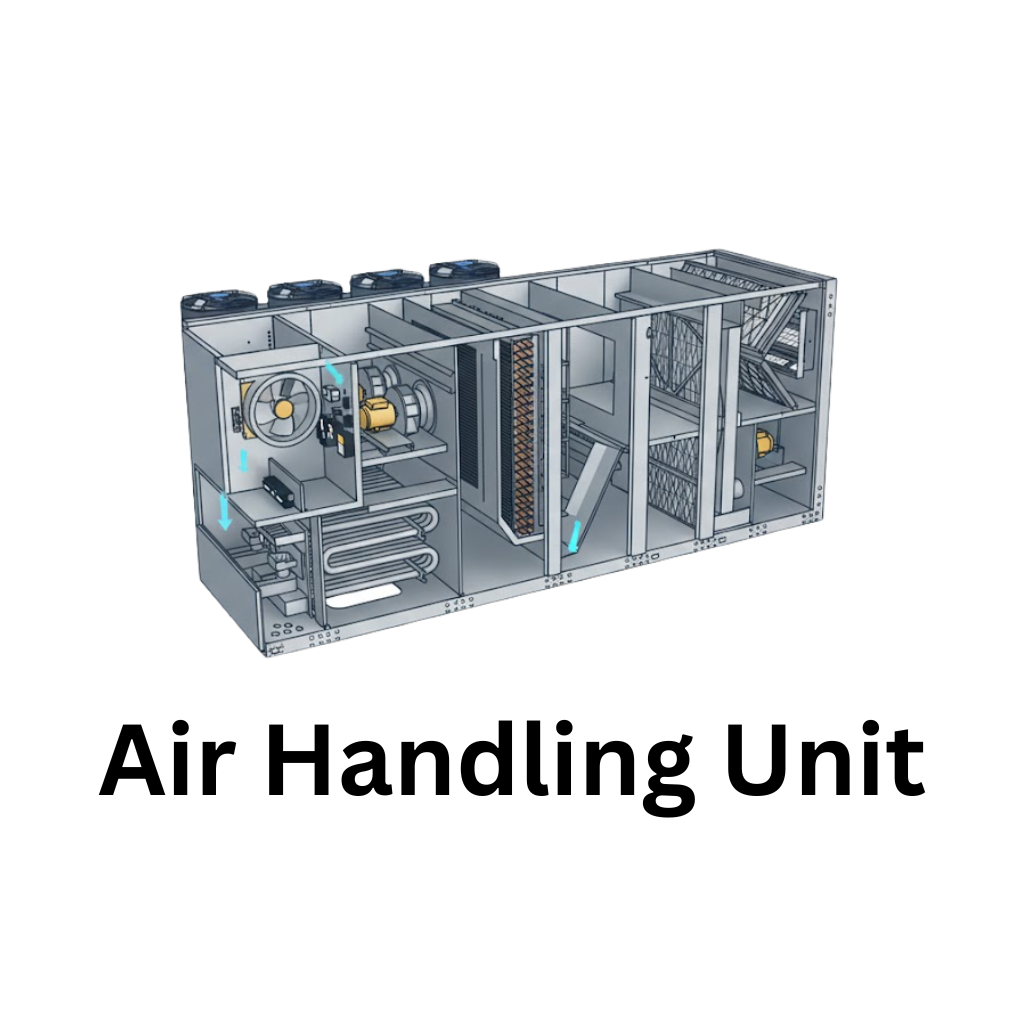

At Gate Corporation, we don't just act as a contract manufacturer; we function as a fully integrated part of your operations. With world-class capabilities in precision machining, sheet metal fabrication, and complex assemblies, we provide the technical excellence you need. But our true value lies in how we embed ourselves in your success.

If you’re ready to move beyond transactional supplier relationships and build a real competitive advantage, let’s have a conversation.

Contact Gate Corporation today to see how a true integrated partnership can transform your supply chain.

.png)