On this page

Data center racks & cabinets: standard sizes, load ratings, earthing, airflow

Most data-center racks are 19-inch EIA-310 frames in 42U–52U height, 600–800 mm width, 1000–1200 mm depth, rated 1000–1500 kg static with front-to-back airflow, bonded to a site earthing bar via a dedicated M8/M10 earth stud; performance depends on correct cable management, blanking, and aisle containment.

What buyers care about (at a glance)

-

Fit: 19″ EIA-310 hole pattern, U-height, and depth clearance for today’s deep servers (1100–1200 mm).

-

Strength: Tested load rating with safety factor (static, dynamic, seismic if required).

-

Grounding: Low-resistance bonding (≤0.1 Ω typical) across doors, side panels, and accessories.

-

Cooling: Unobstructed front-to-back path, high-open-area doors, blanking and brush kits to stop recirculation.

-

Delivery: Factory-installed rails, PDUs, and cable managers to cut deployment time.

Standard sizes (what actually ships and fits)

| Parameter | Typical Options | Notes |

|---|---|---|

| Width | 600 mm (network), 800 mm (server/common) | 800 mm gives side cable space + vertical PDUs |

| Depth | 1000 mm, 1100 mm, 1200 mm | Choose 1100–1200 mm for modern servers & rear cable slack |

| Height (U) | 42U, 45U, 47U, 48U, 52U | Taller = more density; check room height & transport |

| Mounting | 19″ EIA-310 (most common), 21″ OCP, 23″ Telecom | Confirm rail spacing & hole pattern |

| Rails | Square 9.5 mm holes (cage nuts) or tapped 10-32/M6 | Square + cage nuts = flexible accessories |

| Doors | 70–80% open perforated (front), high-open rear | Solid doors only for special filtration use |

Tip: If you’re mixing OEM servers, specify rail adjustability (e.g., 500–900 mm between uprights) and clear U labeling front & rear.

Load ratings (and what the numbers really mean)

-

Static load: Max weight when the rack is fixed on the floor. For enterprise racks: 1000–1500 kg.

-

Dynamic load: Max weight while moving on casters during installation. Typically 60–70% of static.

-

Seismic/NEBS: For quake-prone sites or telco, request GR-63-CORE tested configurations, anchor kits, and bracing.

Manufacturer note:

We publish witnessed test data (deflection, tip, and caster tests). For heavy builds (battery cabinets, dense storage), we add reinforced bases, heavier rails, spreader bars, and through-bolt anchoring.

Parts we manufacture:

Read More

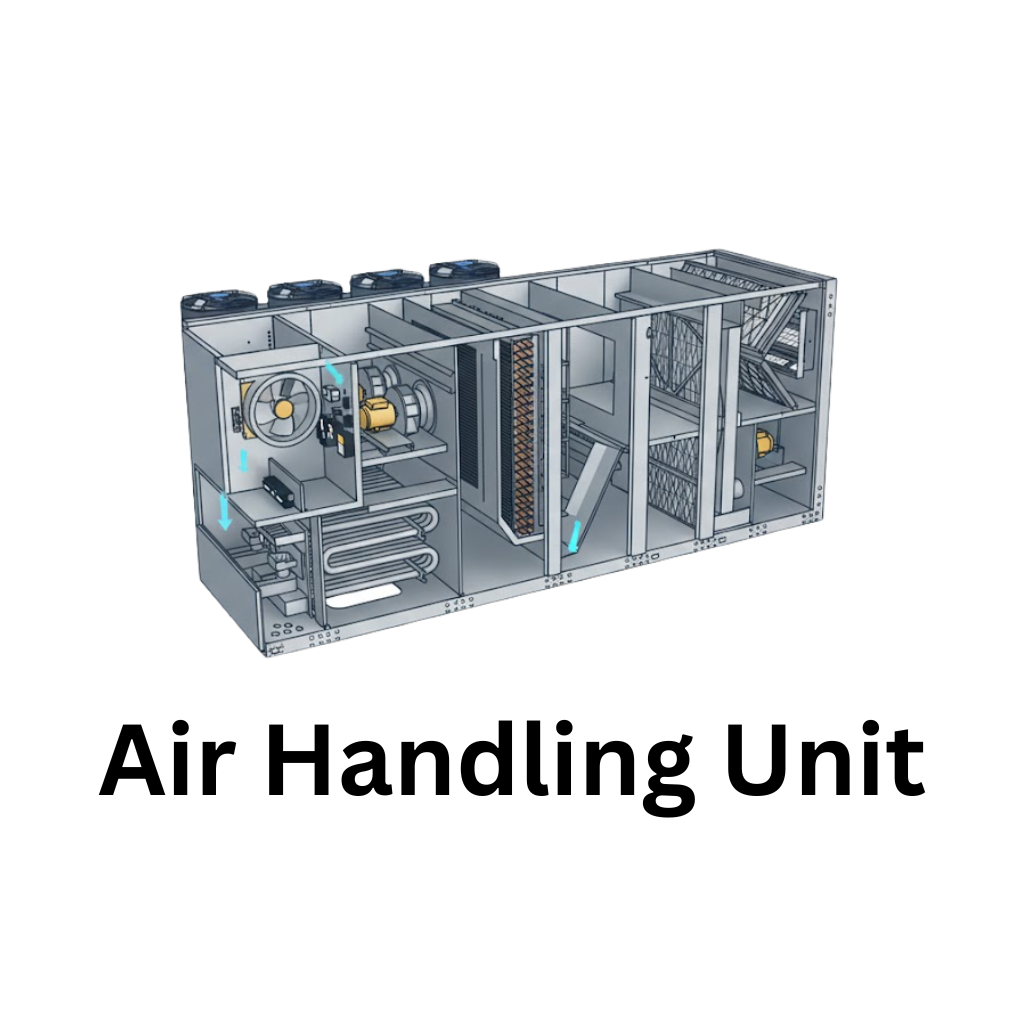

AHU Manufacturing in Saudi Arabia: Why Fabrication Quality Matters More Than Brand Names

Another 5% Cost Reduction This Year? A Friendly Survival Guide for Procurement Teams

If Your Saudi Growth Plan Relies on a Port You Don’t Control — It’s Not a Strategy. It’s a Supply Chain Time Bomb.

Navigating the Red Sea "New Normal": Why Resilient Sourcing is the Future for U.S. Supply Chains

The IMEC Corridor: A Guide for US Business Leaders on the Future of Global Trade

Beyond the PO: A Strategic Guide to the Integrated Vendor Model (IVM)

The Ultimate Guide to Vendor Consolidation: A Step-by-Step Strategy for 2025

Why Warehouse Automation Fails Without Precision Parts | AGV & Racking Insights

Can India Thrive in a World of Tariffs? Pros & Cons

How Suez Canal Expansion Reduces U.S. Supply Chain Costs

How to Handle a Supplier Who Doesn’t Understand Your Requirements

When QA Fails: How to Laugh Through Tears in Manufacturing

.png)