On this page

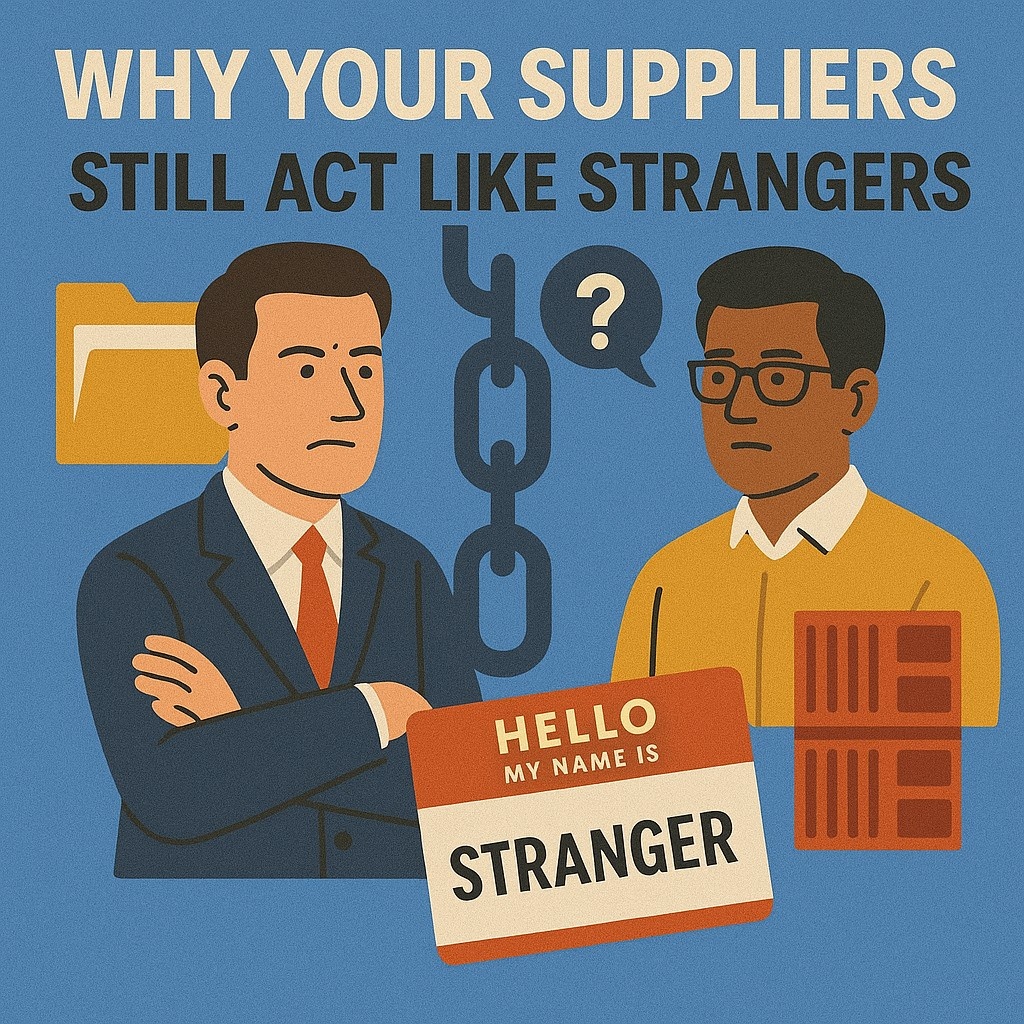

While you are working with suppliers, the most critical factor for success is ensuring that they fully understand your requirements. If they fail to do so, it can result in delays, poor-quality products and put a strain on your relationships. So, what can you do if the supplier doesn’t “get it”?

Let’s walk through some practical steps you can take to address and resolve this issue effectively.

1. Clarify and Document Your Requirements

As basic as it might seem, but often the first step is to make sure your requirements are transparent and communicated thoroughly. A common misunderstanding is usually seen if the specifications are vague or incomplete.

Make sure to:

-

Provide Detailed Specifications: Be as specific as possible about dimensions, materials, tolerances, and timelines. Include technical drawings, blueprints, or any other detailed documents that can eliminate ambiguity.

-

Use Simple Language: If there’s a language barrier, simplify your language. Avoid jargon or idiomatic expressions that might confuse someone not familiar with your industry or language.

-

Document Everything: Create a clear, written document outlining every aspect of the project. This leaves no room for miscommunication and serves as a reference for both parties.

2. Establish Regular Communication

Miscommunication often arises from ambiguous requirements. If your supplier doesn’t fully understand your requirements, they may not ask for clarification and proceed with incorrect assumptions. To prevent this, make communication a priority:

-

Schedule Regular Check-ins: Have frequent, scheduled meetings or calls to discuss progress and address any concerns. This ensures that both parties stay on the same page.

-

Encourage Questions: Make it clear that your welcome questions from the supplier. If they don’t feel comfortable asking for clarification, issues will go unnoticed until it's too late.

-

Use Visual Aids: When words fail, pictures or diagrams can help. Share photos, sketches, or videos that illustrate exactly what you’re looking for.

3. Set Milestones and Provide Feedback

Dividing your project into smaller milestones can help catch mix ups early. Instead of waiting until the project is complete to find out something is amiss, set specific checkpoints where the supplier delivers a portion of the work. At each milestone:

-

Review Deliverables Carefully: Inspect the work in detail and compare it to your requirements.

-

Provide Immediate Feedback: If something’s off, let the supplier know right away. Don’t wait until the final product is ready to address issues.

-

Adjust as Needed: If requirements need to be clarified or updated, do it immediately. This flexibility can prevent major issues down the line.

4. Visit the Supplier’s Facility

Often, the best way to clear up miscommunications is to visit the supplier’s site. A face-to-face meeting can help you convey your requirements more precisely and gain insights into the supplier’s capabilities. During the visit:

-

Demonstrate Your Expectations: Physically show the supplier what you expect in terms of quality and specifications. This can be much more effective than describing it over the phone or email.

-

Evaluate Their Operations: By seeing how they operate, you can assess if they’re truly capable of meeting your requirements.

5. Create a Formal Agreement

If informal communication isn’t getting through, a formal agreement may be necessary. This contract should outline specific expectations, including quality standards, deadlines, and the consequences of not meeting these requirements. Having everything in writing creates accountability and can often prompt a supplier to take your needs more seriously.

6. Work with a Translator or Liaison

If language or cultural differences are creating a barrier, consider working with a translator or local liaison. A professional with knowledge of both your industry and the supplier’s culture can help bridge the gap, ensuring that your instructions are conveyed accurately and understood clearly.

If a supplier consistently fails to understand your requirements, it may be time to explore other options. Working with a supplier who cannot meet your needs can lead to ongoing delays and frustration. Look for a supplier who:

-

Has Proven Experience: Ensure they have a track record of delivering similar products or services.

-

Understands Your Industry: Experience in your sector increases the likelihood they’ll meet your standards.

-

Demonstrates Good Communication: Seek a supplier that values clear communication and understands your requirements from the outset.

Conclusion: Clear Communication is Key

When a supplier misunderstands your requirements, it can be costly and frustrating. The key to resolving this issue lies in clear communication, detailed documentation, and regular feedback. By taking these proactive steps, you can ensure your supplier is aligned with your expectations. If all else fails, don’t hesitate to seek a supplier who can truly deliver.

Ready to enhance your supplier relationships and streamline your manufacturing processes? At GATE Corp, we specialize in empowering businesses to overcome challenges with strategic partnerships and innovative solutions.

.png)