On this page

Most supply chains don't break; they slowly erode under the administrative weight of "vendor sprawl." If your team is buried in redundant RFQs, chasing late shipments, and firefighting quality issues from a dozen different suppliers, you're not alone. According to PwC, 74% of supply chain leaders are actively consolidating vendors to fight this complexity and build resilience.

A fragmented vendor base, often mistaken for flexibility, quietly drains time, margin, and strategic focus. For procurement leaders, especially those managing multiple metal fabrication or component suppliers, the cost is clear: lost negotiation leverage, inconsistent quality, and zero supply chain visibility.

This guide provides a clear, step-by-step framework to consolidate your vendor base with confidence, helping you reduce costs and transform your supply chain into a competitive advantage.

Why Vendor Consolidation is a Strategic Imperative Now

In an environment of shifting tariffs, local content requirements, and rising operational costs, simplifying your supply chain is no longer just an option—it's essential for survival and growth. The business case is backed by hard data:

-

Improve Fulfillment Speed by 20%: A focused partnership accelerates communication and decision-making (McKinsey, 2024).

-

Reduce Total Cost of Ownership (TCO) by 12%: Consolidation leads to better pricing, reduced logistics costs, and lower administrative overhead.

-

Decrease Product Launch Costs by 15%: Involving a strategic partner early in the design phase minimizes costly downstream changes (BCG, 2023).

A 6-Step Framework for a Smooth Vendor Consolidation

Transitioning from five or more suppliers to a single strategic partner can seem daunting. This proven framework ensures you can make the shift smoothly, without disrupting your operations.

Step 1: Map and Benchmark Your Current Vendor Base

Before making any changes, you need a complete picture of your current state. Conduct a thorough audit of every supplier, documenting:

-

SKUs and part categories they supply

-

Quality scores (e.g., defects per million or PPM)

-

On-Time In-Full (OTIF) delivery performance

-

Compliance certifications (ISO, industry-specific standards)

-

Normalized pricing (per unit, per kg, etc.) to allow for true apples-to-apples comparison.

Goal: Create a data-driven baseline to identify performance gaps, pricing inconsistencies, and overlapping capabilities.

Step 2: Identify Redundancies and Mitigate Risks

Using your audit data, segment your suppliers to highlight friction points. Pinpoint:

-

Multiple vendors supplying the same or similar parts.

-

Suppliers who are chronically late or have high defect rates.

-

Partners lacking critical ESG, compliance, or cybersecurity documentation.

-

High-cost suppliers whose performance doesn't justify the premium.

Goal: This isn't just about cutting suppliers; it's about strategically pruning sources of risk, cost, and inefficiency from your supply chain.

Step 3: Define Your Ideal Strategic Partner Profile

Your consolidated partner must be more than just a low-cost producer. The ideal profile includes strategic capabilities that drive long-term value. Look for a partner who offers:

-

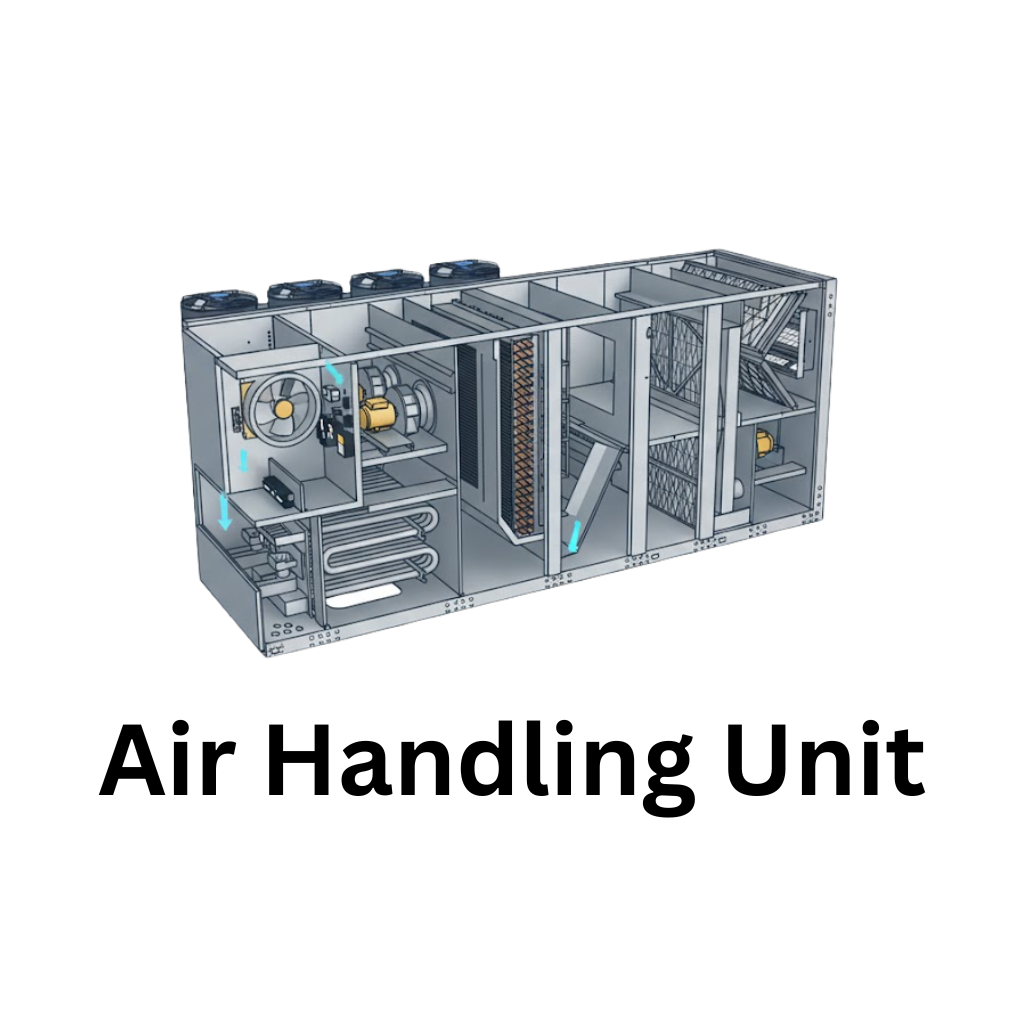

Multi-Capability Manufacturing: The ability to handle diverse processes (e.g., sheet metal, precision machining, extrusion, casting, and assembly) under one roof.

-

Design for Manufacturability (DFM) Support: Engineering expertise to collaborate on early-stage design, prototyping, and value engineering.

-

Global Footprint with Local Presence: The ability to manufacture near your key end markets to reduce logistics costs and lead times.

-

Robust Quality and Compliance Systems: Proven frameworks that align with your industry's standards.

Step 4: Evaluate for Long-Term Fit, Not Just Unit Cost

With your ideal profile defined, shortlist candidates and evaluate them based on their strategic fit. Prioritize partners who:

-

Have deep experience in your industry vertical (e.g., Solar, HVAC, Automation, EV).

-

Demonstrate scalable capacity to grow with your business.

-

Offer in-house engineering and tooling capabilities.

-

Are financially stable and open to long-term agreements (LTAs) or co-investment.

Step 5: Execute a Phased Pilot Program

To minimize risk, avoid a "big bang" transition. Start with a structured pilot program for your top candidate:

-

Begin with a small batch of low-risk, non-critical SKUs.

-

Operate under a 90-day test contract with clear deliverables.

-

Conduct weekly performance reviews on quality, delivery, and responsiveness.

-

Pro-Tip: Keep 1-2 legacy suppliers on standby during the pilot phase to ensure business continuity.

Step 6: Build a Shared Performance & KPI Dashboard

Once the pilot is successful, formalize the relationship. Move beyond the traditional PO model by creating a joint performance dashboard that tracks shared KPIs, such as:

-

Lead time consistency

-

First-pass yield and quality metrics

-

Forecast accuracy

-

Jointly-owned cost reduction initiatives

-

Tooling efficiency and uptime

Goal: This transforms the relationship from a transactional one into a true performance-driven partnership where both parties are aligned on success.

The Result: From Reactive Procurement to a Resilient Supply Chain

By moving from vendor fragmentation to a strategic partnership, you gain a powerful competitive edge built on:

-

Complete Supply Chain Visibility

-

Lower Landed Costs and Higher Margins

-

Faster Engineering Feedback and Innovation Cycles

-

Stronger Negotiating Leverage

Most importantly, you reclaim valuable time and resources, allowing your team to focus on forward-looking strategy instead of reactive problem-solving.

Consolidate with Confidence with Gate Corporation

Ready to move from vendor chaos to a controlled, cost-effective supply chain? Gate Corporation is the multi-capability manufacturing partner built to make your consolidation a success.

We offer the comprehensive services you need under one strategic umbrella—from precision machining and sheet metal fabrication to complex assemblies and DFM support. We don't just supply parts; we partner with you to optimize your designs, streamline your logistics, and drive down your total cost of ownership.

Contact our experts today for a consultation on how we can help you build a simpler, stronger, and more profitable supply chain. here

.png)