On this page

You open your inbox.

Subject: FY25 cost-down target.

Buy the same stuff for less. Again.

If your eye just twitched, you’re not alone.

Every procurement team knows this moment. Another financial year, another savings target, and the same question: How do we squeeze 5% more out of suppliers who already gave their best price last year?

The truth is, you won’t get there by chasing another round of discounts. The cost isn’t just in the quote — it’s in the design, process, and how your supply chain is managed.

The Real Problem

Procurement leaders are constantly asked to deliver savings while maintaining quality, delivery, and stock levels. But the traditional “negotiate harder” approach has hit a wall.

Costs are built into the system — in specifications, lot sizes, freight, and approvals — not just in the supplier margin.

Fix those levers, and the savings come naturally. Push only on price, and you get short-term wins with long-term headaches.

The real savings come from how parts are designed, made, packed, and planned — not just from who supplies them.

Where Procurement Costs Really Come From

Hidden costs creep in quietly through everyday decisions. Here’s where most teams lose money without realizing it:

-

Specs that are tighter than needed: Don’t pay for aerospace-level tolerances when you just need reliable function.

-

Too many parts and steps: Two welded pieces that could be one formed piece waste both time and cost.

-

Wrong process for the job: Machining what should be stamped, or casting what should be machined, drives unnecessary expense.

-

Tiny orders and rush buys: Small lots and emergency orders cause setup waste and expensive freight.

-

Inefficient packing and shipping: Half-empty cartons and frequent partial shipments burn cash quietly.

-

Unplanned inventory: Without min/max levels, everything becomes “urgent” — and urgent means costly.

-

No link to raw material indexes: Metal prices move; if your price doesn’t, you end up renegotiating every quarter.

These are the levers that matter. Fix them, and the savings are real — not just theoretical.

A Simple Plan: 15 / 30 / 60

You don’t need a year-long project to start cutting procurement costs. A focused, 60-day plan can deliver results fast.

Next 15 Days – Quick Wins

-

Review your top-spend parts with Engineering. Relax tolerances and finishes where it’s safe.

-

Bundle POs and set blanket orders for repeat items.

-

Improve packing density and set a steady ship cadence.

Result: 2–4% savings and fewer last-minute expedites.

Next 30 Days – Structural Fixes

-

Run a VA/VE or DFM session (Value Engineering + Design for Manufacturing). Combine parts, optimize stock sizes, and remove waste.

-

Pilot a Vendor-Managed Inventory (VMI) or simple Kanban system on 10–15 items.

-

Move to index-linked pricing for metals or coatings with a clear monthly report.

Result: Another 4–6% total cost reduction and better inventory turns.

By 60 Days – Durable Advantage

-

Shift parts to the right process as volumes grow (machined → formed or extruded).

-

Localize production only when it actually reduces landed cost and risk.

-

Build should-cost models for your top parts to guide future negotiations.

Result: 10–12% sustainable savings, predictable pricing, and fewer quality issues.

How We Partner With You

We don’t just supply parts — we act as an extension of your engineering and procurement team.

Here’s how we help you hit your cost targets without the usual friction:

-

Manufacturing engineers on day one: We run DFM/VA-VE reviews, check GD&T and tolerance stacks, and send redlines ready for your approval.

-

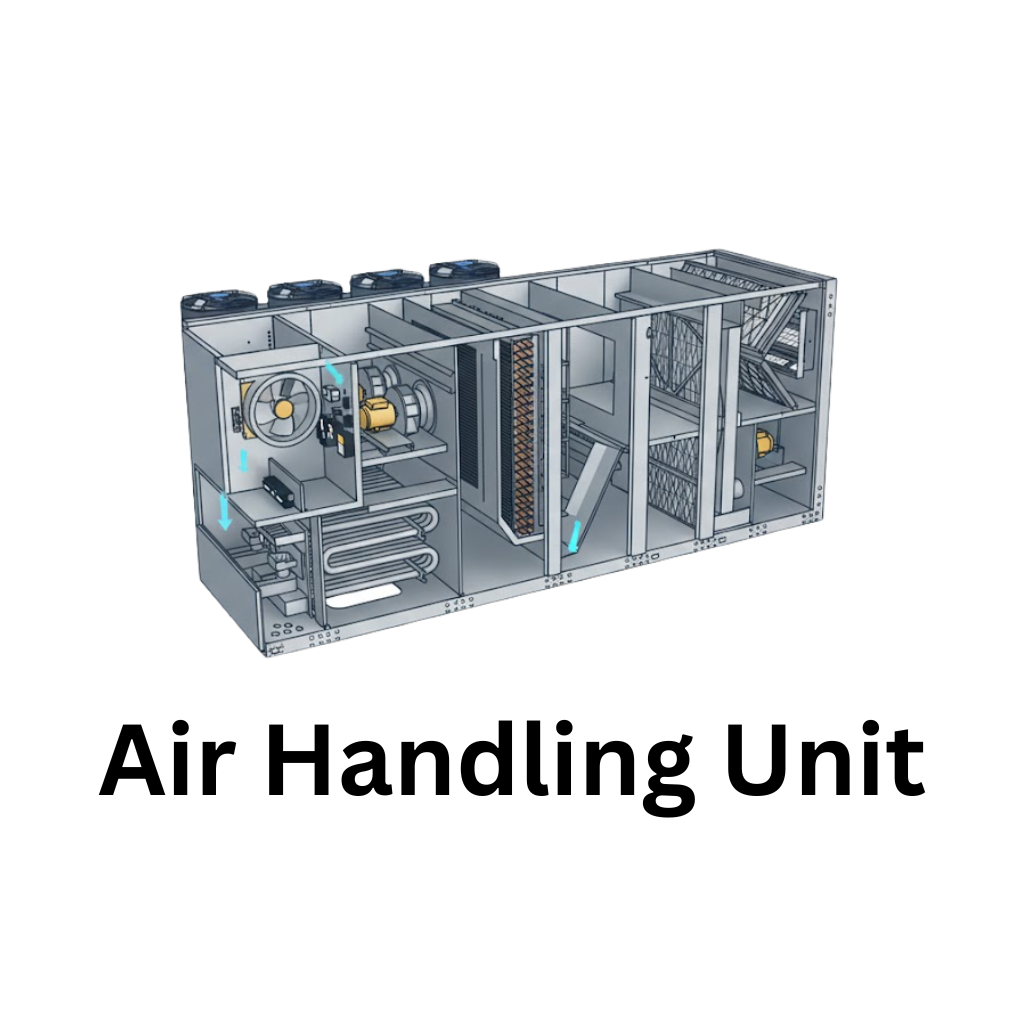

Right process, right part: Sheet metal, machining, casting, extrusion — matched perfectly to your volume and geometry.

-

Tooling and fixtures in-house: Faster iterations, better cycle times, lower rework.

-

Proof before purchase: Rapid prototypes, pilot runs, and first-article reports that Engineering can trust.

-

Operational control: VMI/Kanban systems with agreed min/max levels and service targets.

-

Transparent pricing: Index-linked agreements and volume bands your CFO can actually track.

-

Logistics tune-up: Pack density, palletization, and pooled lanes — lower freight, fewer damages.

Quick Real-World Wins

-

Carton Tetris: Re-engineered packing to remove a pallet per shipment. Freight costs dropped instantly.

-

First-article proof before EOQ change: Engineering signed off early; cost reduction was immediate.

-

Capacity reservation instead of expedites: On-time delivery improved, and rush fees disappeared.

-

Tolerance reset: Relaxed one hole position, removed a second operation, and reduced both lead time and cost.

-

Two-into-one redesign: Replaced two welded parts with one formed component — fewer fixtures, fewer defects.

What Your Dashboard Sees

-

Lower purchase price and lower total cost

-

Fewer urgent shipments

-

Better on-time delivery

-

Healthier inventory turns

-

Savings your CFO actually believes (because they’re measured and reported)

Ready for a Quick Win?

If you’re staring down another “5% cost-down” target, let’s make it easier.

We’ll review a few parts together, identify fast wins, and outline a plan you can take straight to Finance.

Book a quick session → here

.png)