On this page

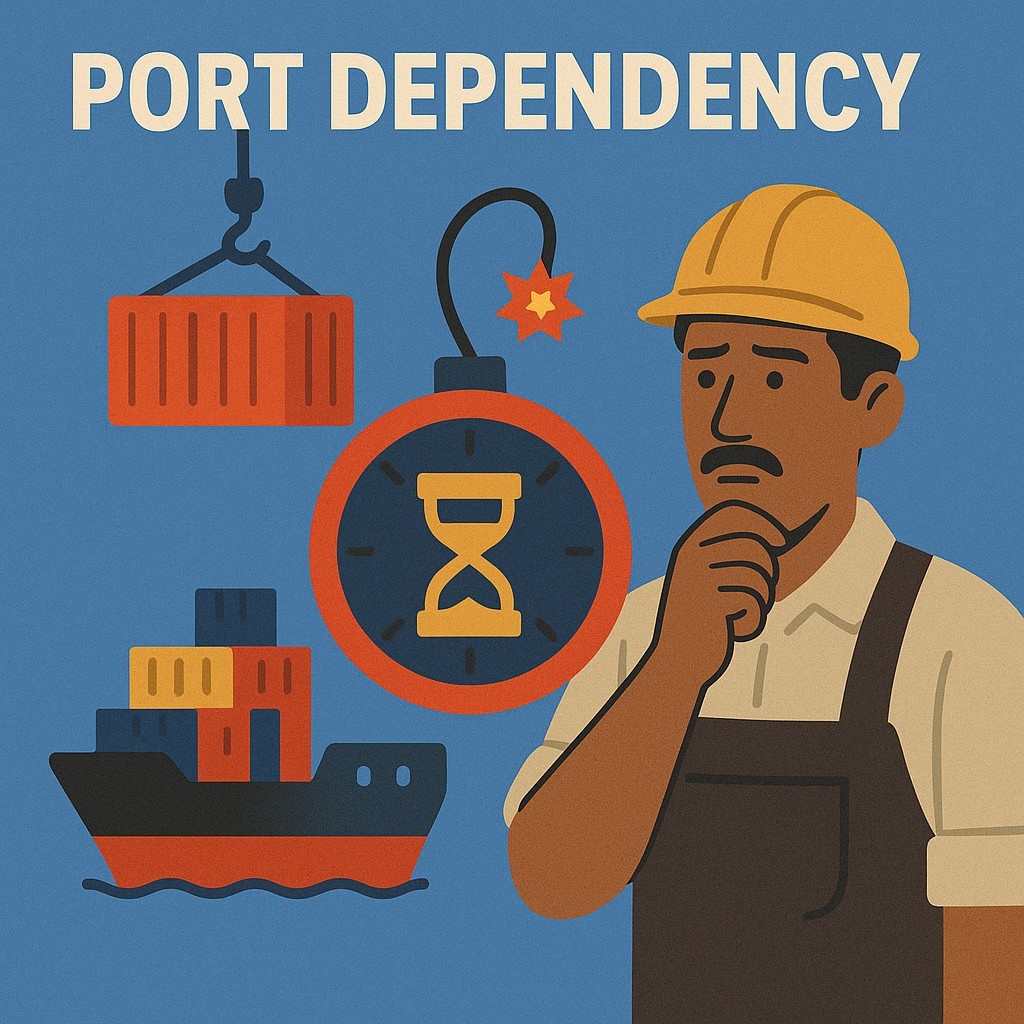

Ever felt like your business growth is tied to someone else's schedule? For many manufacturers, especially here in Saudi Arabia, the answer is a resounding "yes." You’ve invested in production, talent, and innovation, but a single bottleneck – a port you don't directly control – can throw everything into chaos. It’s a common manufacturing growth challenge that can quickly turn a promising expansion into a frustrating standstill.

The Hidden Cost of Port Dependency

When your entire outward or inward flow of goods hinges on external port operations, you're exposed to significant port dependency risk. Think about it: delays, unexpected fees, labor disputes, or even geopolitical shifts far beyond your control can directly impact your bottom line. Suddenly, your carefully laid plans for expansion, market entry, or even just consistent delivery are derailed.

This isn't just about minor inconveniences; it’s about serious operational and financial consequences. Production lines can halt, customer commitments might be missed, and your reputation, built on reliability, can suffer. For Saudi-based manufacturers, navigating these waters means understanding that external port reliance isn't just a logistical hurdle—it’s a strategic vulnerability.

Strategic Resilience: Building Your Ironclad Supply Chain in KSA

The true solution isn't reactive firefighting; it's about embedding foresight and control into your entire operational DNA. For leading manufacturers in Saudi Arabia, building supply chain resilience Saudi Arabia is no longer just a buzzword – it's a strategic imperative that directly impacts your market leadership and shareholder value.

Here's how you, as a discerning manufacturer, can fundamentally shift your approach to strengthen your own supply chain:

-

Champion In-Kingdom Value Creation: This means actively localizing your own supply base and optimizing internal production processes within KSA. By strategically cultivating domestic suppliers for critical components and raw materials, and partnering with engineering-backed local manufacturers who can support your product from initial design to final delivery, you reduce lead times, minimize reliance on volatile international shipping lanes, and align directly with Vision 2030's goals. This proactive approach to strategic sourcing MENA not only de-risks your operations but also directly contributes to boosting your local content score and fostering a stronger, self-reliant industrial ecosystem that benefits your bottom line and speed to market.

-

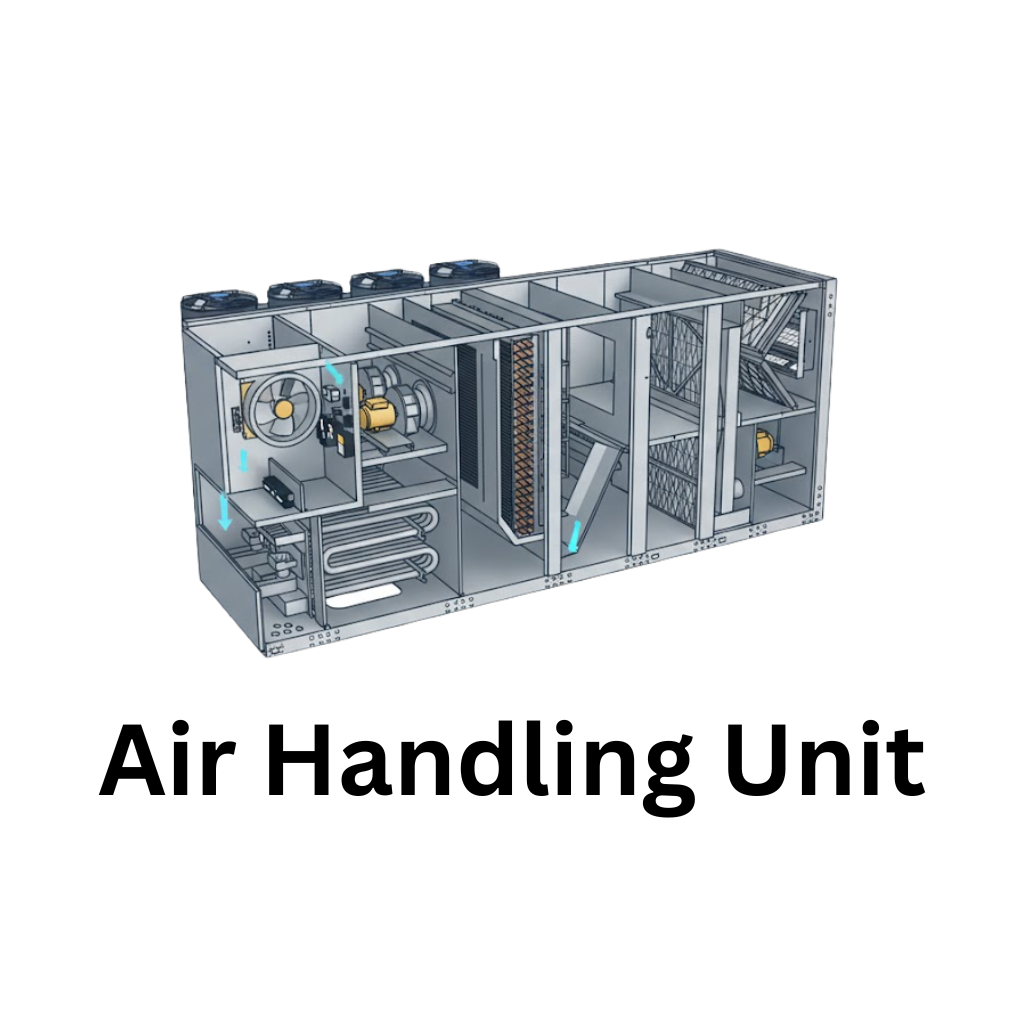

Invest in Your Own Intelligent Logistics & Data Visibility: True logistics optimization KSA starts from within your factory gates. This involves implementing advanced analytics, IoT sensors, and AI-driven platforms to gain comprehensive, real-time visibility across your entire value chain. By understanding your inventory, production flow, and inbound/outbound movements with precision, you can anticipate disruptions, optimize production schedules, and make data-driven decisions that protect your operational continuity and profitability, rather than merely reacting to external events.

-

Forge Strategic Ecosystem Partnerships: Resilience is a shared endeavor. As a manufacturer, you are a pivotal player in a broader ecosystem. Proactively initiate and cultivate strategic alliances not just with logistics providers, but also with technology innovators, research institutions, and even other local manufacturers. By participating in these collaborative networks, you can share knowledge, co-invest in solutions, and collectively build a more adaptable and secure supply chain that enhances your company's agility and reduces individual vulnerabilities.

Your Growth Deserves a Strategy, Not a Gamble

Your business deserves a growth plan built on certainty, not on the fluctuating schedules of a port you don’t control. By proactively addressing port dependency risk and investing in true supply chain resilience, Saudi manufacturers can transform potential time bombs into pathways for sustained, predictable growth.

Take control of your logistics destiny. It’s not just about moving goods; it’s about safeguarding your future.

The Future of Saudi Manufacturing: In Your Hands

Ultimately, the future of manufacturing in Saudi Arabia hinges on strategic foresight, not just operational efficiency. Taking control of your supply chain, embracing in-Kingdom value creation, leveraging data, and forging collaborative partnerships aren't merely best practices; they are foundational pillars for sustainable, predictable growth that you can drive from within your own organization.

The era of passive reliance on external factors is over. By actively building resilience, investing in local capabilities, and maximizing your contribution to the Kingdom's industrial vision, you transform potential supply chain vulnerabilities into powerful competitive advantages. It's about safeguarding your business, contributing to national prosperity, and charting a course for true manufacturing leadership in KSA.

What steps will you take to fortify your supply chain and secure your future in Saudi Arabia's dynamic manufacturing landscape?

.png)