On this page

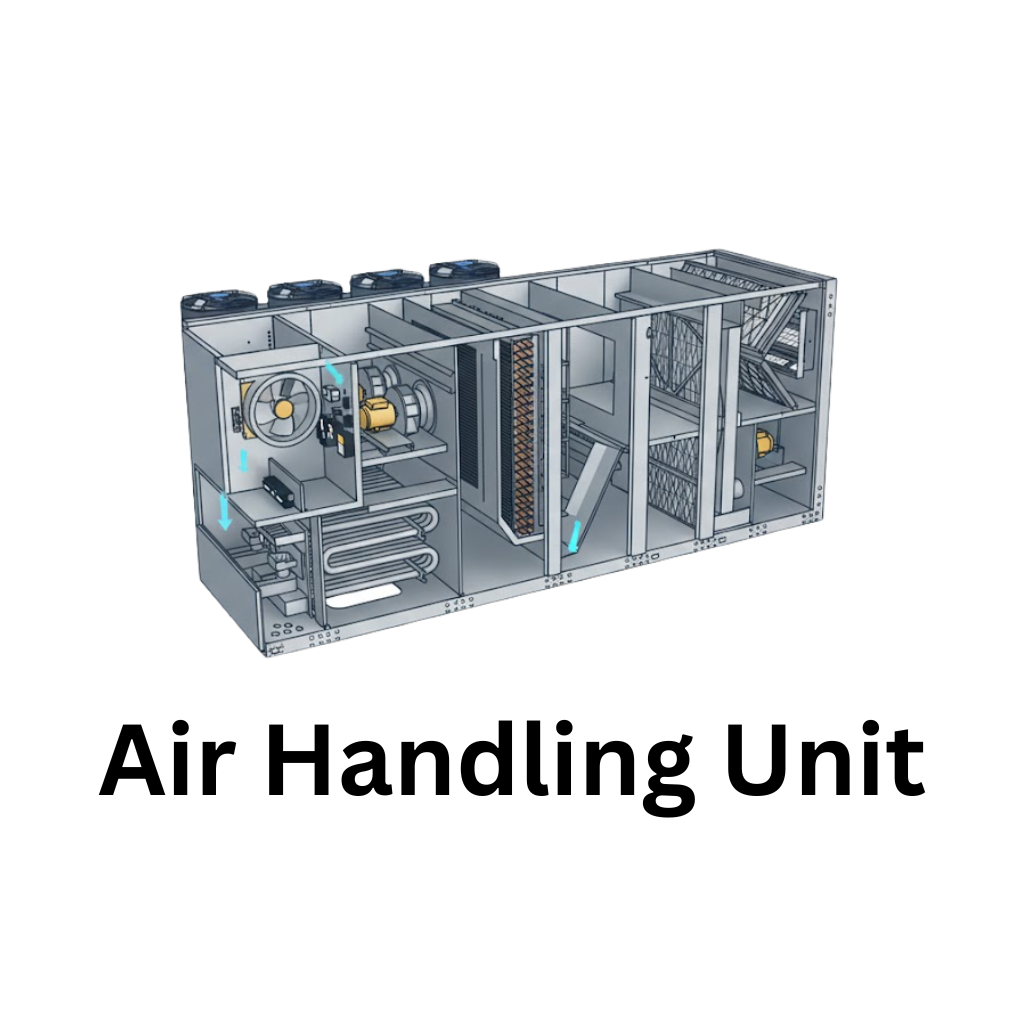

Most AHU discussions in the Middle East revolve around fans, coils, filters, and controls. Yet the long-term performance of an AHU — airflow stability, hygiene, leakage rate, noise, energy use, and corrosion life — actually depends on something procurement teams often overlook:

How the AHU cabinet, frame, doors, and internal assemblies are fabricated.

In large Saudi projects, the AHU may come from a recognized brand, but problems still appear on site:

-

access doors leak or bend

-

panels absorb moisture

-

drain pans rust in months

-

base frames deform when lifted

-

coil casings don’t align

These failures rarely originate from the “brand.”

They originate from weak fabrication methods.

Understanding fabrication quality helps procurement heads select better, negotiate smarter, and reduce lifetime cost — without increasing equipment cost.

The Fabrication Ecosystem Behind AHUs

A commercial or industrial AHU in Saudi Arabia is built from over 150 fabricated parts. Before motors and coils are installed, an AHU passes through:

1) Structural Frame Fabrication

-

Aluminum extrusions or galvanized steel

-

Corner connectors

-

Mechanical or welded joining

-

Base frame design critical for rooftop and crane lifting

A weak frame leads to vibration, door alignment issues, and panel leakage over time.

2) Panel and Insulation Engineering

Panels are more than “skins.” They dictate leakage, hygiene, and thermal performance.

-

Double-skin panels

-

PU/PIR foam injection, foam-in-place, or mineral wool

-

Thermal break choices

-

Steel or aluminum sheet thickness

Poor insulation causes condensation and microbial growth — a major concern in hospitals and coastal cities.

3) Door and Gasket Engineering

AHU access doors handle repetitive maintenance stress.

Technical focus areas often ignored during procurement:

-

hinge torque rating

-

door frame rigidity

-

EPDM gasketing compression

-

latch system design

-

leakage class compliance

A door built with the wrong gasket compression ratio will leak permanently after a few maintenance cycles.

4) Coil Casing and Filter Holding Systems

These components dictate airflow uniformity and hygiene.

Precision-cut filter racks, proper sealing channels, drainage slope of coil casing, and corrosion protection impact lifespan and static pressure. Minor dimensional deviations produce major leakage, bypass air, and poor filtration results.

5) Coating and Corrosion Strategy

Saudi’s coastal humidity, industrial zones, and desert sand mean coatings can’t be generic.

Choices affect 15+ year lifespan:

-

polyurea coating

-

epoxy coat

-

powder coat

-

galvanized G90/G140

-

stainless steel passivation

Incorrect coating means you’re literally buying corrosion.

Why Procurement Should Split AHU Components Strategically

In Saudi Arabia, complete AHU procurement ties buyers to international lead times, irrelevant seasonality, and logistical delays. But not every part needs to be imported.

A smarter approach is to localize fabrication-heavy components inside KSA, while still sourcing critical engineered parts (fans, motors, coils, BMS controls) internationally or from your existing vendor.

Localizing allows you to:

✔ reduce delivery time without compromising technology

✔ improve IKTVA/local content score

✔ customize to site requirements (rooftop loading, narrow shafts, heavy duty frames)

✔ prevent bending, leakage, or coating failures through local QA access

✔ avoid factory rework after site inspection failures

This approach is already being adopted by data centers, large hospitals, and giga-projects seeking higher availability without overpaying for OEM branding.

Procurement Checklist: Fabrication Quality Indicators for AHUs

If you want an AHU that performs, ask your supplier about:

| AHU Component | What to Check | Why It Matters |

|---|---|---|

| Panels | Foam type, density, thermal break | Leakage, condensation, hygiene |

| Doors | Gasket compression, latch quality | Avoid bypass & noise |

| Base Frame | Weld or bolted rigidity, coating | Lifting & rooftop vibration |

| Drain Pan | Slope, stainless grade, coating | Prevent microbial growth |

| Coil Casing | Tolerance, thickness, coating | Improve coil efficiency |

| Filter Rack | Precision sealing channel | Better IAQ & fan efficiency |

If your vendor can’t answer these confidently, procurement is buying risk — not equipment.

AHU Localization Under Vision 2030 and IKTVA

Saudi Arabia’s industrial policy rewards companies that:

-

develop local fabrication capability

-

reduce import dependence

-

partner with KSA manufacturers

-

create local QA and engineering collaboration

Localizing AHU fabrication aligns perfectly with this direction, without altering technical design standards or international approvals.

It’s not a cost compromise.

It’s a supply chain and performance upgrade.

The Future of AHUs in Saudi Arabia Is Fabrication-Led, Not Brand-Led

As Saudi projects grow in scale and complexity, procurement strategy must evolve beyond “best unit price.” Project risk, lifetime cost, and failure points all sit in fabrication engineering.

The winners will be companies that:

-

keep OEM technology

-

localize AHU cabinets, internal structures & base frames

-

build long-term QA partnerships with Saudi fabricators

-

combine international parts + Saudi manufacturing efficiency

This is where the next decade of HVAC competitiveness will be decided.

👉 Want to See How This Model Works?

We can show you:

📌 real fabrication workflows

📌 sample QA checkpoints

📌 insulation, coating, and frame engineering guidelines

📌 how global brands adapt for Saudi fabrication

Book a discovery discussion with our engineering team - here

Let’s build AHUs that don’t fail on site.

.png)